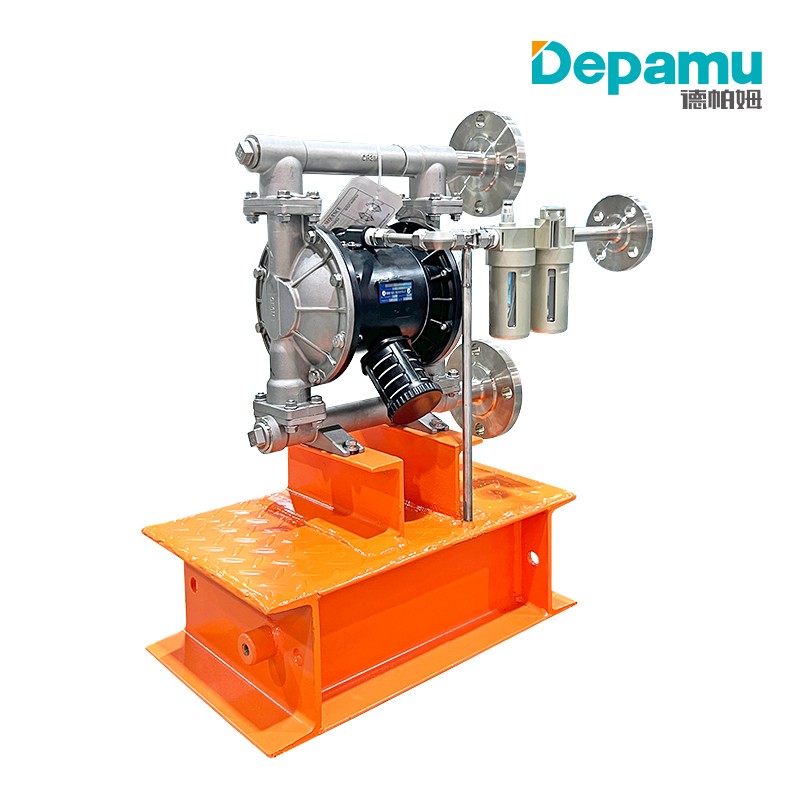

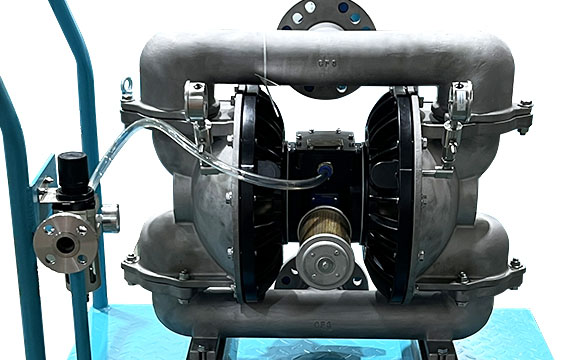

Pneumatic diaphragm pump DPQR-25

Under adoption of the most advanced European technologies, pneumatic pumps can replace all kinds of imported pneumatic diaphragm pumps.

Pneumatic pumps can replace diaphragm pumps

Under adoption of the most advanced European technologies, pneumatic pumps can replace all kinds of imported pneumatic diaphragm pumps.

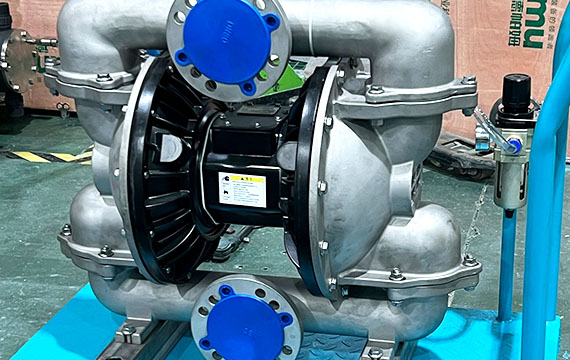

Water irrigation or diversion is not needed, the suction head lift reaches 7m, the head lift reaches 50 m and the outlet pressure is 6 kgf/cm²;

Pump advantages

Under smooth flow and good passing performance, the maximum allowable diameter of passable particles is 10 mm; Slurry or sundry pumping brings little wearing to a pump;

Head lift and flow can be steplessly adjusted via air valve opening; A pump can work while immersed in fluids;Liquids relatively viscous can be transported as well (with a viscosity below 10,000 cP);

No Oil lubrication

Oil lubrication is not required for a pump with no influence on it even when idling.Different materials can be chosen as per different fluids and anti-corrosion structure can avoid leakage.

- Data sheet

| Max Discharge Pressure | 95 MPa |

| Max Discharge Flow Rate per Pump Head | 12100 L/h |

| Flow rate can besteplessy adjusted in the range | 0-100% |

| Metering accouraoy reaches | ±0.5% |

Complete Guide

Pneumatic diaphragm pump DPQR-25

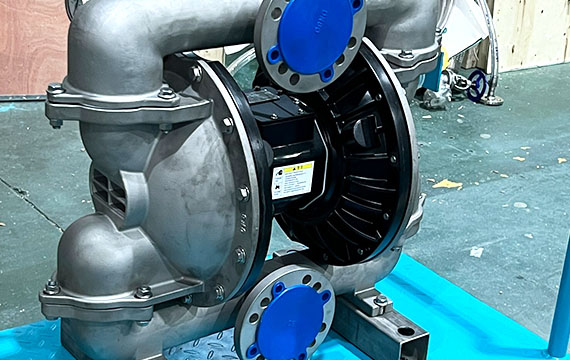

Working principle, The motor drives worm gear pair, changes rotary motion of the motor into reciprocating movement of the slide rod through the eccentric mechanism, the slide rod drives the mechanical diaphragm to perform periodical deformation, thus realizing fluid suction and discharge.

Max Discharge Pressure:95 MPa;Max Discharge Flow Rate per Pump Head: 12100 L/h;Flow rate can besteplessy adjusted in the range of 0-100%'Metering accouraoy reaches ±0.5%;

A pump head can be made of 304, 316, 316L, 904, Hastelloy C, PVC, PVDF, PP, PTFE, etc.

- Under adoption of the most advanced European technologies, pneumatic pumps can replace all kinds of imported pneumatic diaphragm pumps.

- Water irrigation or diversion is not needed, the suction head lift reaches 7m, the head lift reaches 50 m and the outlet pressure is 6 kgf/cm²;

- Under smooth flow and good passing performance, the maximum allowable diameter of passable particles is 10 mm;

- Slurry or sundry pumping brings little wearing to a pump;

- Head lift and flow can be steplessly adjusted via air valve opening;

- A pump can work while immersed in fluids;

- Liquids relatively viscous can be transported as well (with a viscosity below 10,000 cP);

- Oil lubrication is not required for a pump with no influence on it even when idling

- Different materials can be chosen as per different fluids and anti-corrosion structure can avoid leakage.

It is widely used in industries of environment protection, pharmaceutical, paper, sewage treatment, urban water supply, cement grinding aid, new energy, etc.