The Best High Pressure Process Hose Pump Manufacturer

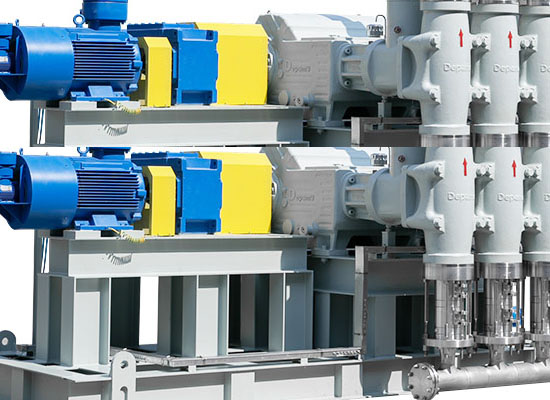

The driver drives the crankshaft after speed reduction and torque increase in the reducing mechanism, the crank connecting rod mechanism converts rotary motion of crankshaft to reciprocating motion of piston, which pushes hydraulic oil in hydraulic chamber. Hydraulic oil transmits piston thrust force and volumetric change, acting on hose diaphragm. Hose diaphragm is subject to cyclical squeezing under force transmitted by hydraulic oil, leading to cyclical compression and relaxation of internal fluid chamber in hose diaphragm, thus producing volumetric change. Continuous fluid delivery is realized under combined action of inlet and outlet check valve assemblies.

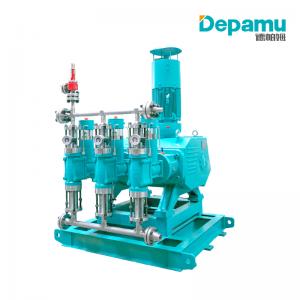

High Pressure Process Hose Pump

Wide application to industries like petrochemical, coal chemical, lithium battery, new material, mining, metal lurgy, energy, environmental protection

Wide application to industries like petrochemical, coal chemical, lithium battery, new material, mining, metal lurgy, energy, environmental protection

Wide application to industries like petrochemical, coal chemical, lithium battery, new material, mining, metal- lurgy, energy, environmental protectio

Wide application to industries like petrochemical, coal chemical, lithium battery, new material, mining, metal lurgy, energy, environmental protection

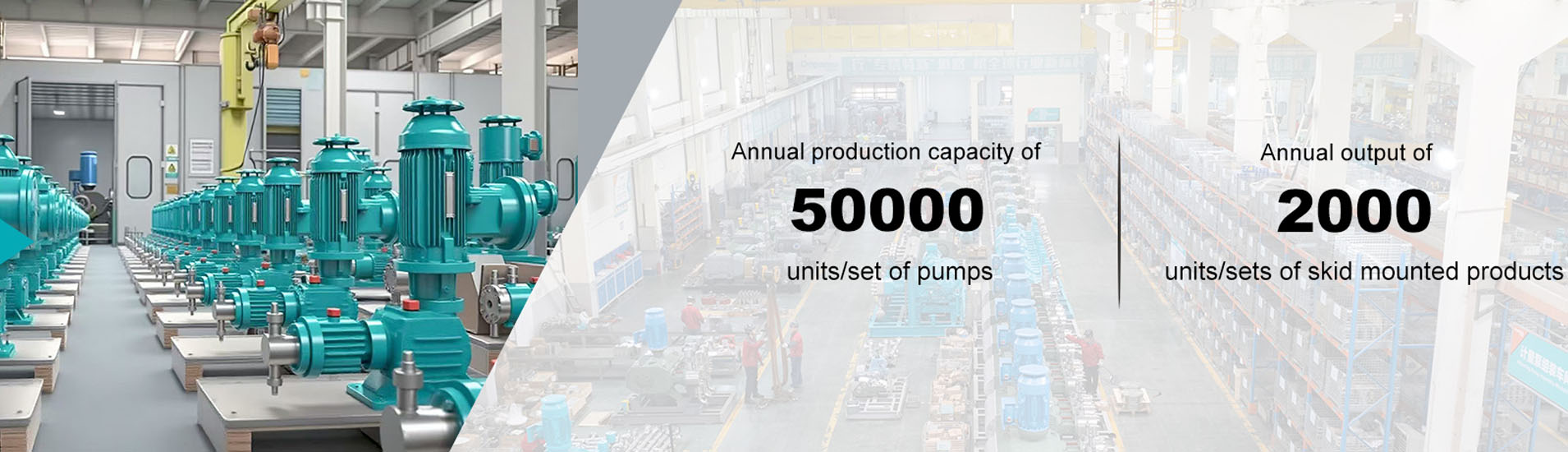

High Pressure Process Hose Pump Workshop

Wide application to industries like petrochemical, coal chemical, lithium battery, new material, mining, metal- lurgy, energy, environmental protection, pharmacy, etc., especially suitable for delivery of highly viscous fluids with particles.

- Capacity:≤ 450m³/h

- Pumping Temperature:≤ 120℃

- Discharge Pressure:≤ 35MPa

- Fluid Viscosity:< 1500cP

- Fluid Solid Content:≤ 80%