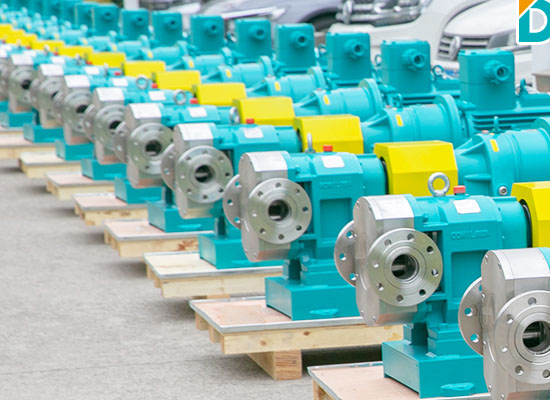

The Best Rotor Pump Manufacturer

Depamu rotor pumps, stars among displacement pumps, are designed as per API 676. With a compact structure and a small mounting space, lobe pumps are widely applied to working conditions in multiple industries. With various options for rotor materials and pump mounting types, they can better satisfy actual customer demands. Besides, thanks to the completely symmetric structure, a simple change in driving direction can achieve change in pump transfer direction. Under adoption of modular design, Depamu rotor pumps includes 5 series and 7 models with a capacity range of 0.1~10000m³/h, a temperature range of 40℃~280℃ and the maximum discharge pressure of 2.0MPa. Pumps of a same series share the same rotor, gear, bearing, axial lining board and mechanical sealing.

Rotor Pump

Depamu rubber pumps are displacement pumps and the working principle is: elastomeric wide-blade rotor based on 5-axis linkage or 3-dimensional flow pr

Depamu rubber pumps are displacement pumps and the working principle is: elastomeric wide-blade rotor based on 5-axis linkage or 3-dimensional flow p

Depamu rubber pumps are displacement pumps and the working principle is: elastomeric wide-blade rotor based on 5-axis linkage or 3-dimensional flow pr

Depamu rubber pumps are displacement pumps and the working principle is: elastomeric wide-blade rotor based on 5-axis linkage or 3-dimensional flow pr

Depamu rubber pumps are displacement pumps and the working principle is: elastomeric wide-blade rotor based on 5-axis linkage or 3-dimensional flow pr

Depamu rotor pumps, stars among displacement pumps, are designed as per API 676. With a compact structure and a small mounting space, lobe pumps are w

Depamu rotor pumps, stars among displacement pumps, are designed as per API 676. With a compact structure and a small mounting space, lobe pumps are w

Depamu rotor pumps, stars among displacement pumps, are designed as per API 676. With a compact structure and a small mounting space, lobe pumps are w

Depamu rotor pumps, stars among displacement pumps, are designed as per API 676. With a compact structure and a small mounting space, lobe pumps are w

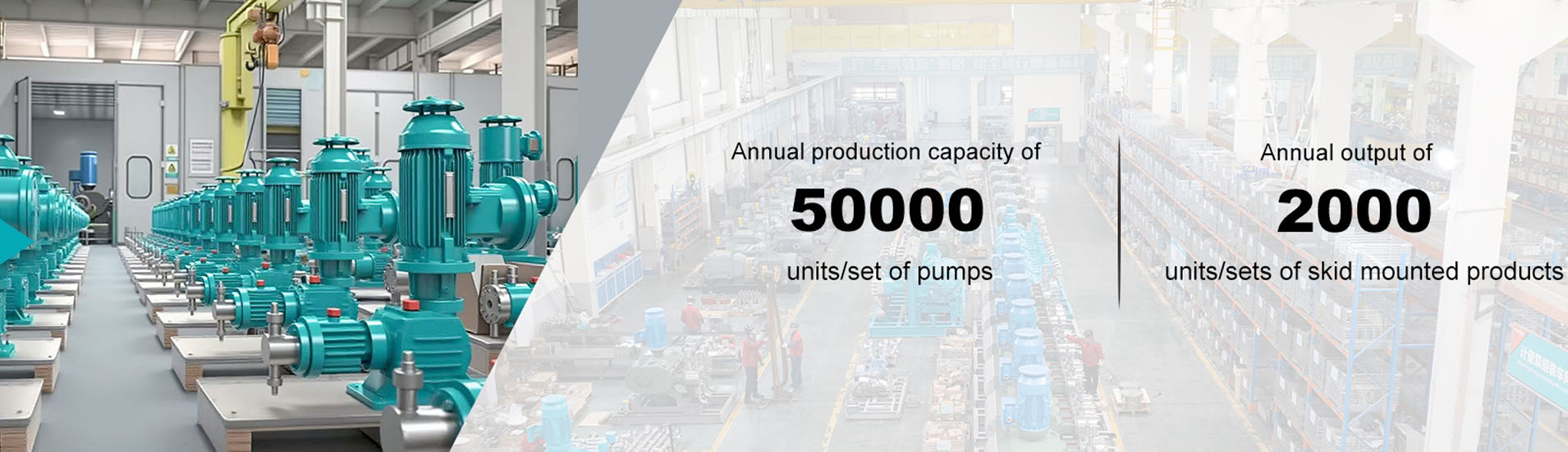

Rotor Pump Workshop

Depamu rotor pumps includes 5 series and 7 models with a capacity range of 0.1~10000m³/h, a temperature range of 40℃~280℃ and the maximum discharge pressure of 2.0MPa. Pumps of a same series share the same rotor, gear, bearing, axial lining board and mechanical sealing.

- Simple compact structure and beautiful appearance

- Stableand reliable running,long service life

- Low noise, high efficiency, convenient maintenance and easy replacement of wearing parts

- Unique patented products with replaceable rotor tips

- Large seal chamber fit for various mecha nical seals

- Constant capacity to delivery any fluid