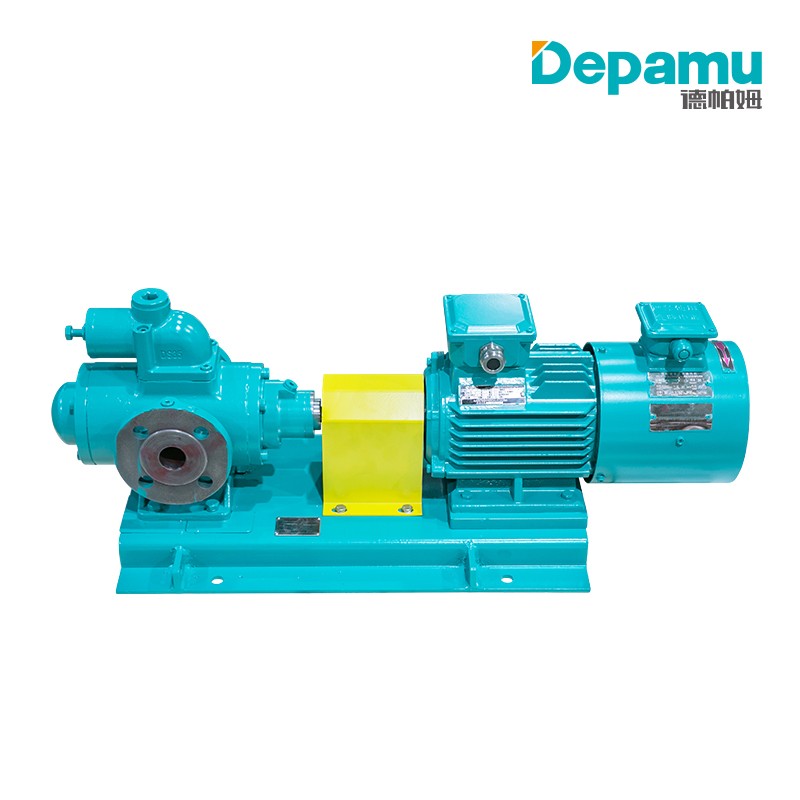

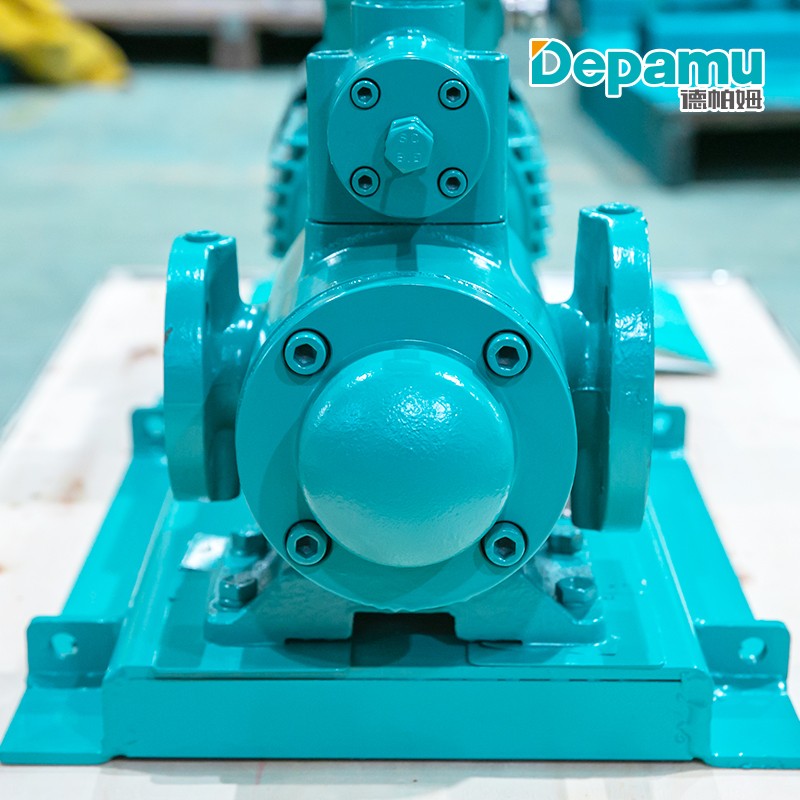

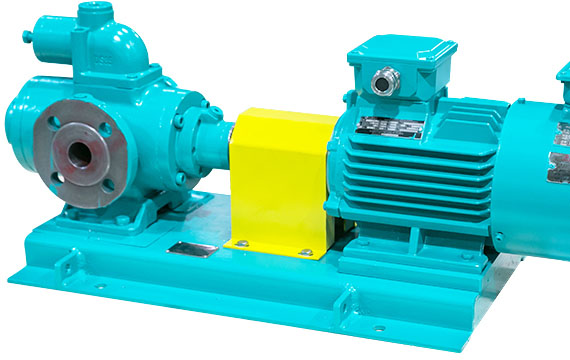

Three Screw Pump CLSNH40-46F1-C1

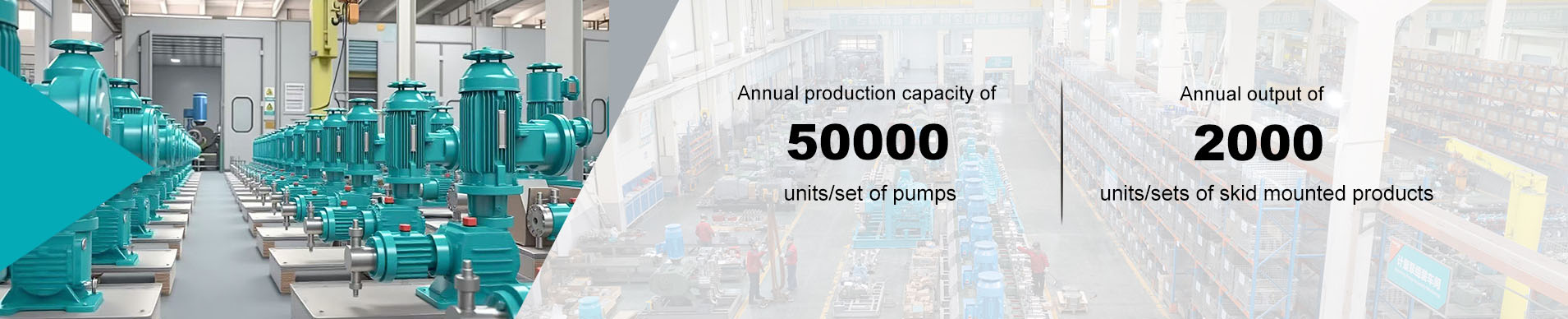

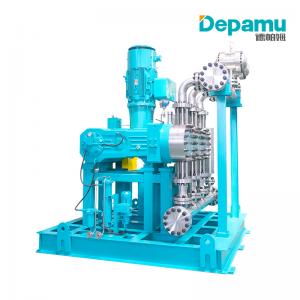

Based on advanced German technologies and professional technology certification, Depamu three screw pumps show obvious superiority in terms of special working conditions like a high viscosity, a high pressure, a high temperature, etc. featuring a long service life, few faults and reliable operation, and have won praise from users at home and abroad with many patents held of the first-rank interna

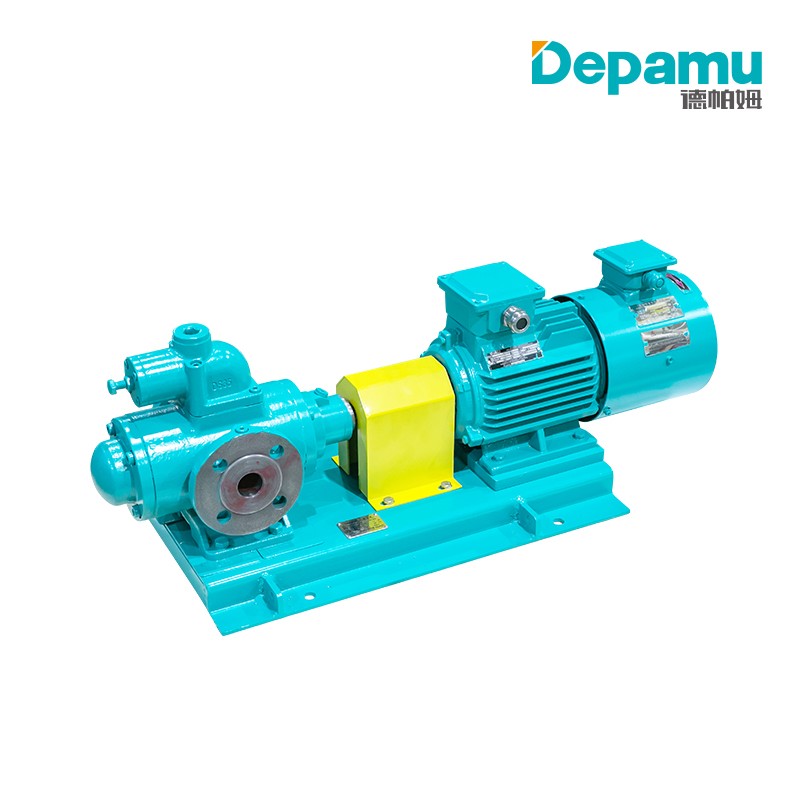

Long life & Strong self-priming capacity

Uniform and continuous flow, no pulsation, high volumetric efficiency, low noise, service life remarkably longer than that of a gear pump or rotor pump.

Strong self-priming capacity, no need in bottom valve or auxiliary evacuating equipment, reliable operation.

Small size & high speed allowed

Compact structure, small size, light weight,

high speed allowed, not too sensitive to gases or pollutants, direct driving allowed by a motor or other prime mover.

High temperature resistance & easy maintenance

Pumped fluid without foam or turbulence, highly viscous and high-temp fluid transport allowed.Durable structure, easy mounting and maintenance.

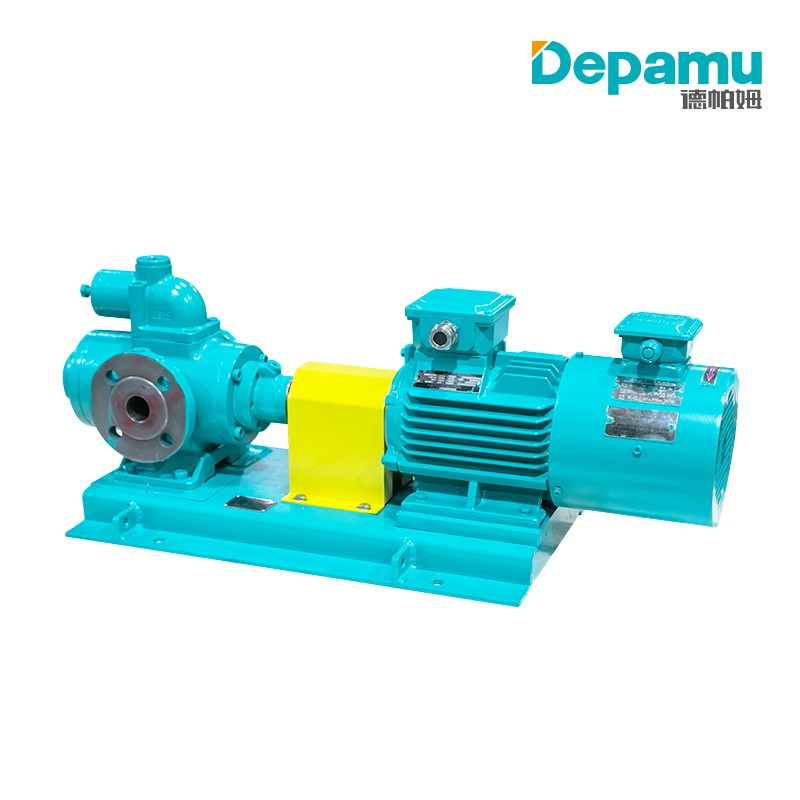

- Data sheet

- Specification

| Capacity | max.456m³/h max.7600L/min |

| Differential Pressure | 20bar,max.40bar |

| Speed | max.2900r/min |

| Fluid Viscosity | 3~760cSt |

| Max. Temperature | 300℃ |

Complete Guide

Three Screw Pump CLSNH40-46F1-C1

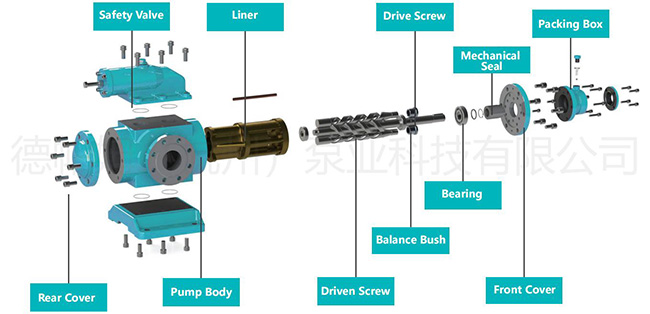

Working principle,A three screw pump is a rotary positive displacement pump with the working principle below: continuous and separated enclosed cavities are formed by exact matching of a pump body (or three-hole liner) with three parallel and symmetric intermeshing screws; when the drive screw rotates, fluid is sucked in the enclosed cavities, which move axially continuously in a constant speed with rotation of the drive screw, thus transferring fluid from the inlet to the outlet of the pump and realizing pump pressure increase.

Application for delivery of fuel oil, lubricating oil, hydraulic oil and other lubricating liquids similar to oil in various fields like petroleum, architecture, chemical fiber, metallurgy, Li-ion battery, machinery, electricity, machine tool, shipping, glass, food, environmental protection, water treatment, highway, etc. In industrial field, three screw pumps are used as lubricating pumps; they're used as hydraulic pumps in a hydraulic system, transfer and boost pumps in a fuel oil system, and transfer and oil filling pump in a transfer system.

The drive screw rotates, driving rotation of the two driven screws, and an oil film is formed between the drive screw and the driven screws; because of the oil film, the driving screw and the driven screws will not contact, thus reducing screw wearing and ensuring a long service life of the pump.

A three screw pump is applicable to transfer of lubricating fluids with no corrosive substance or chemical erosion for pump components, such as lubricating oil, mineral oil, synthetic hydraulic oil and natural oil. It can also be used for transfer of other special lubricating fluids like light fuel oil, heavy fuel oil, coal tar, hard pitch, viscose, emulsion, etc. Please refer to corresponding product catalogue for correct model selection and pump application.

- A SN three screw pump, a rotary positive displacement pump, with a helical profile composed of by special-shape curves, transfers fluid via change in volume of screw meshing space during operation. In axial direction of the drive screw, intermeshing of the pump body and the screws forms continuous and separated enclosed cavities, fluid is sucked in those cavities and moves axially continuously in a constant speed with rotation of the drive screw, thus transferring fluid from the inlet to the outlet of the pump.

- A pump can be equipped with a safety valve (except for special structures) for protection against overpressure, and the safety valve can't be used as a system overflow valve.

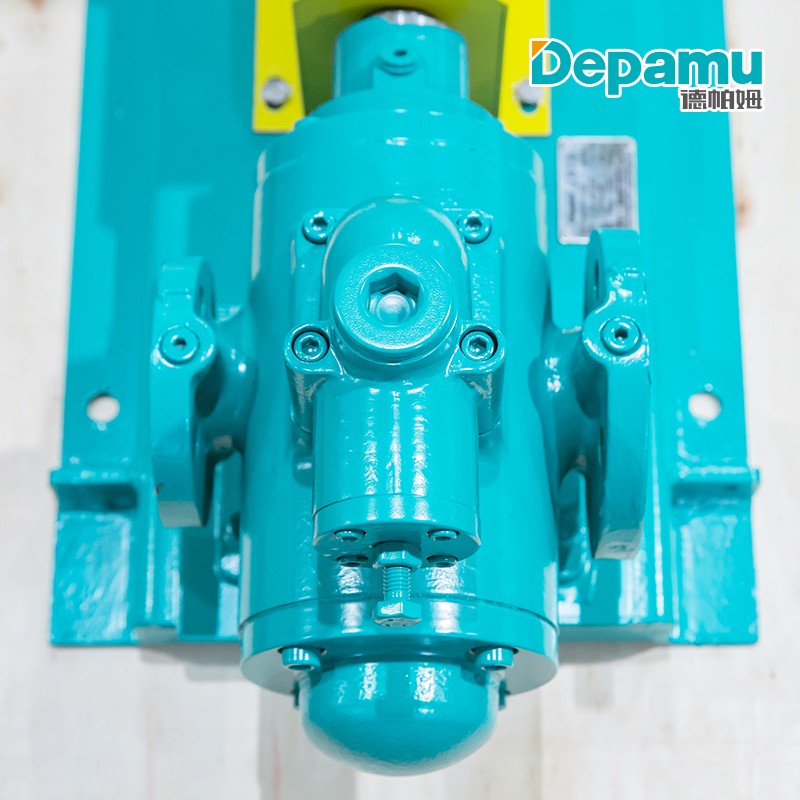

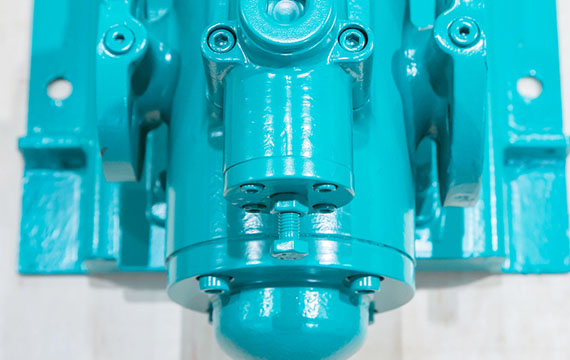

- According to pumped fluid and operating temperature, shaft seals for DPSN series are divided into F1 and F2 types, and a pump body can be a single-layer pump body or a double-side welded pump body.

- Uniform and continuous flow, no pulsation, high volumetric efficiency, low noise, service life remarkably longer than that of a gear pump or rotor pump.

- Strong self-priming capacity, no need in bottom valve or auxiliary evacuating equipment, reliable operation. Compact structure, small size, light weight

- high speed allowed, not too sensitive to gases or pollutants, direct driving allowed by a motor or other prime mover.

- Pumped fluid without foam or turbulence, highly viscous and high-temp fluid transport allowed.

- Durable structure, easy mounting and maintenance.