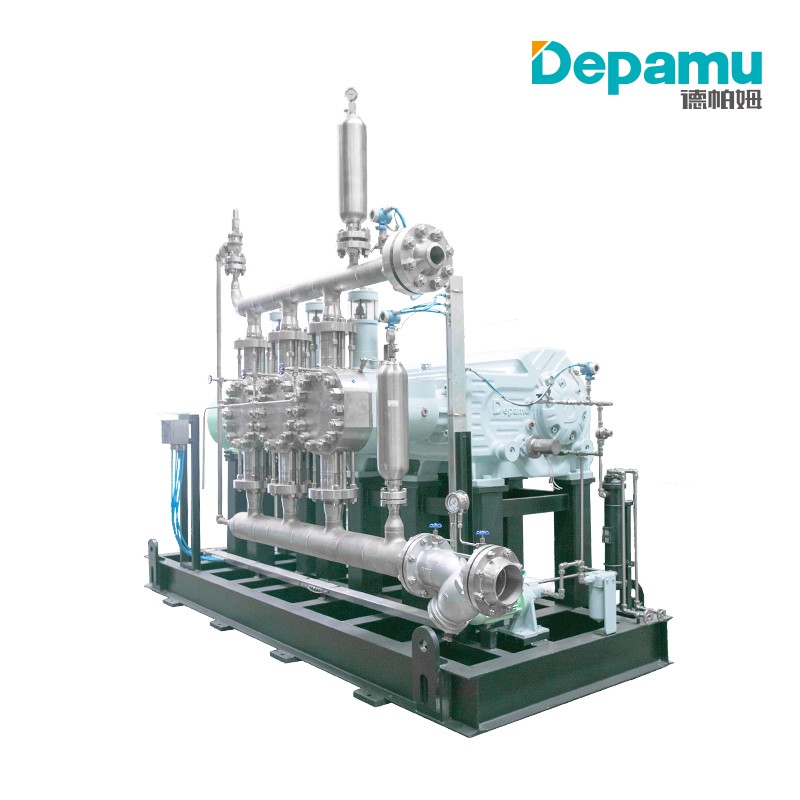

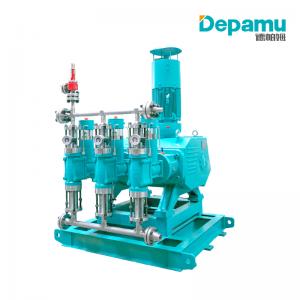

High-pressure Reciprocating Pumps 3HD130G-MSBD-16-14.5-III

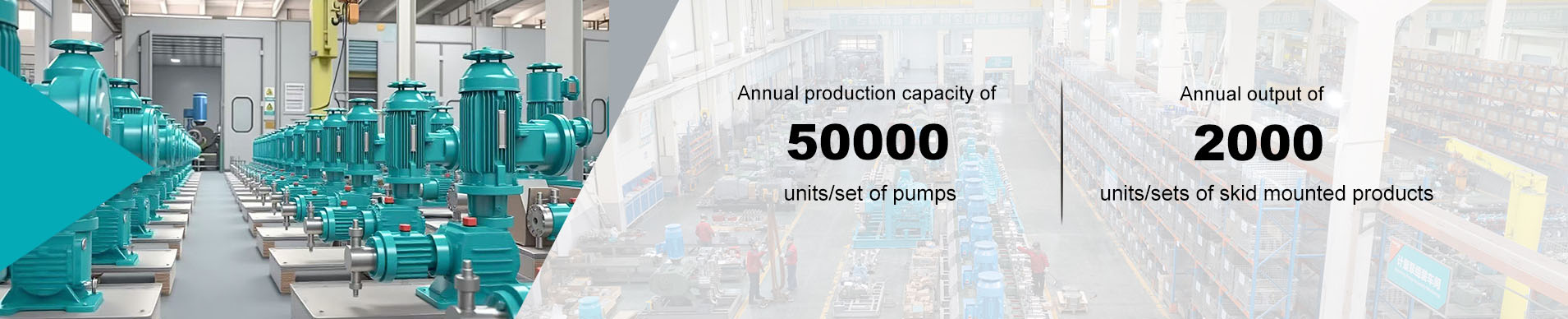

Based on solid technologies, reciprocating pumps are especially popular in various fields. High-pres- sure plunger reciprocating pumps feature high

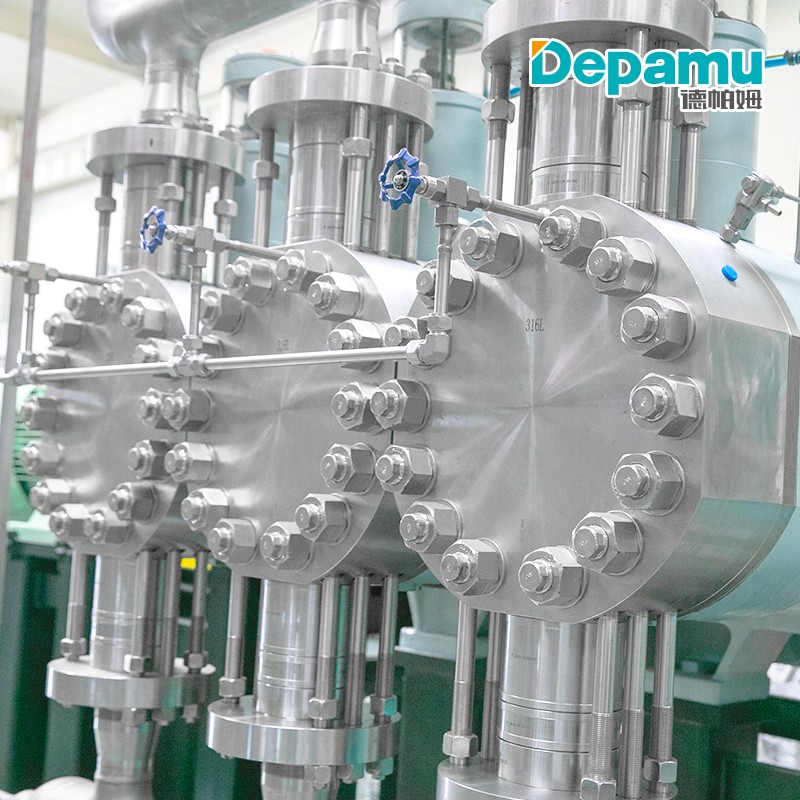

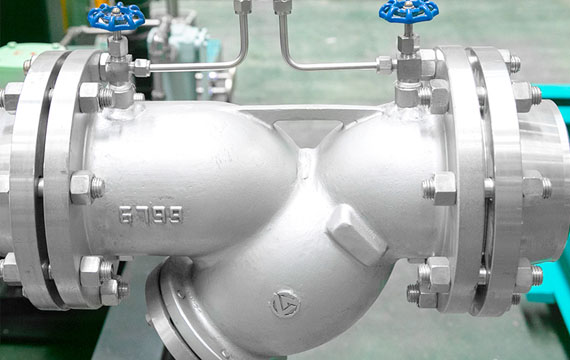

Diaphragm isolation structure & modular design

Diaphragm isolation structure provided at pump liquid end and fully-enclosed fluid chamber ensuring no leak, thus realizing transfer of toxic, hazardous, flammable and volatile fluids;

Liquid end in modular design and with flexible configuration as per detailed fluid characteristics to meet various service conditions.

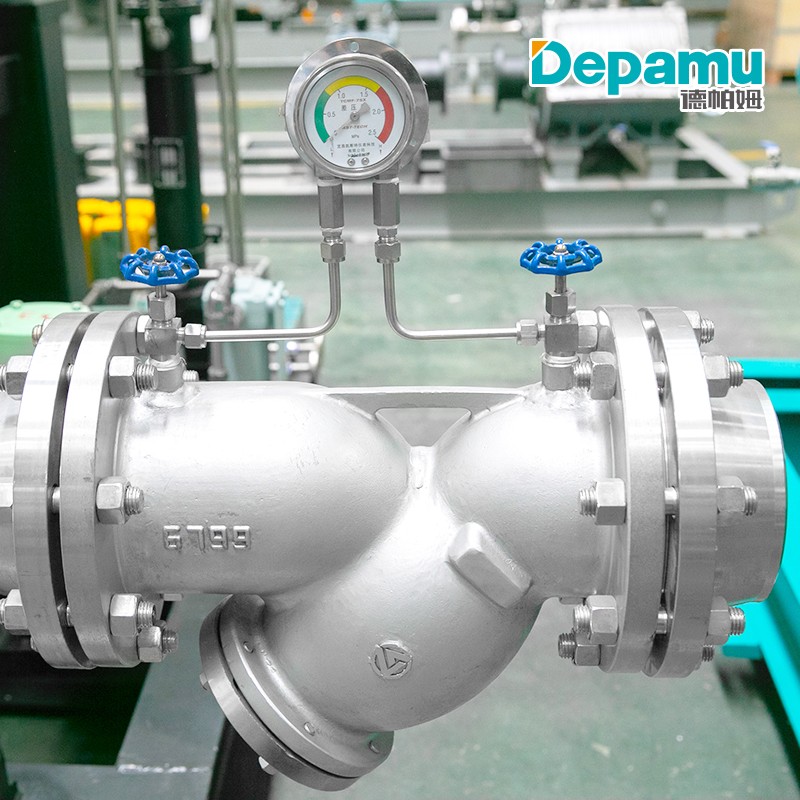

Double diaphragm rupture alarm device

Double diaphragm rupture alarm device configurable to realize real-time diaphragm state monitoring, ensuring short-period continued pump operation in case of either diaphragm rupture accidentally, thus conducting planned maintenance under pump shutdown and avoiding loss;

Pump Advantages

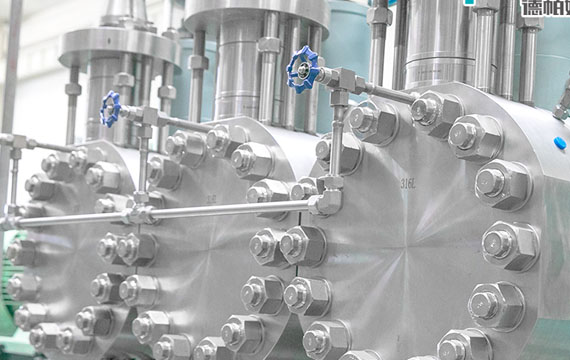

Mechanical oil compensation valve assembly in hydraulic chamber with combined working of limit valve, vent valve and internal relief valve, to reliably maintain a stable oil volume in hydraulic chamber, thus maintaining long-term stable pump operation;

Forced fluid transfer via volume change, high pump transfer efficiency, and stable discharge capacity free from influence by pressure fluctuation in pump discharge pipeline;

- Data sheet

| Capacity | 1.02-14.53m³/h; |

| Discharge Pressure | 4.9-35.4MPa |

| Pumping Temperature | -40 ~ 150℃ |

| Fluid Viscosity | ≤3000cP |

Complete Guide

High-pressure Reciprocating Pumps 3HD130G-MSBD-16-14.5-III

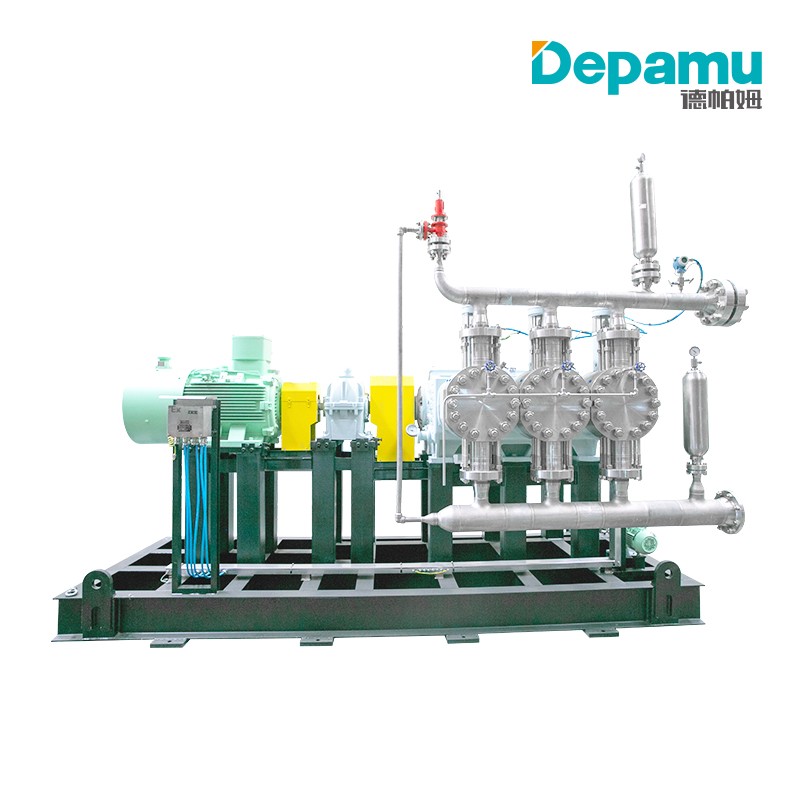

Working principle, High-pressure process diaphragm pump is a type of positive displacement pump with a fully-enclosed fluid chamber ensuring no fluid leak, and realizing fluid transfer through cyclical forced change in the volume of the working chamber.

DEPAMU reciprocating pumps, designed as per American Petroleum Institute standard (API674), can represent quality at a worldwide leading level, and many patents the company has obtained can prove that. Products can meet extremely severe service conditions, transport materials accurately and reliably. Based on solid technologies, reciprocating pumps are especially popular in various fields. High-pres- sure plunger reciprocating pumps feature high efficiency, compact structure, stable performance, reliable and safe operation.

304, 316, 316L, 2Cr13, duplex stainless steel, Ti alloy and other metals available for choice.

- Efficient and durable pump drive end in various types like external reducer, external belt pulley, internal worm gear, internal double helical gear, etc. to meet requirements under different severe service conditions.

- Liquid end is in different types of structures including plunger, planar diaphragm and hose diaphragm.

- The plunger type is comparatively simple while the diaphragm type ensures no fluid leaking and shows excellent corrosion resistance.

- Whole-process intelligent control can be realized through online real-time monitoring and control of signals for pressure, capacity, temperature rise, vibration, diaphragm rupture, etc.

- Personalized customization is available as per specific customer requirements.

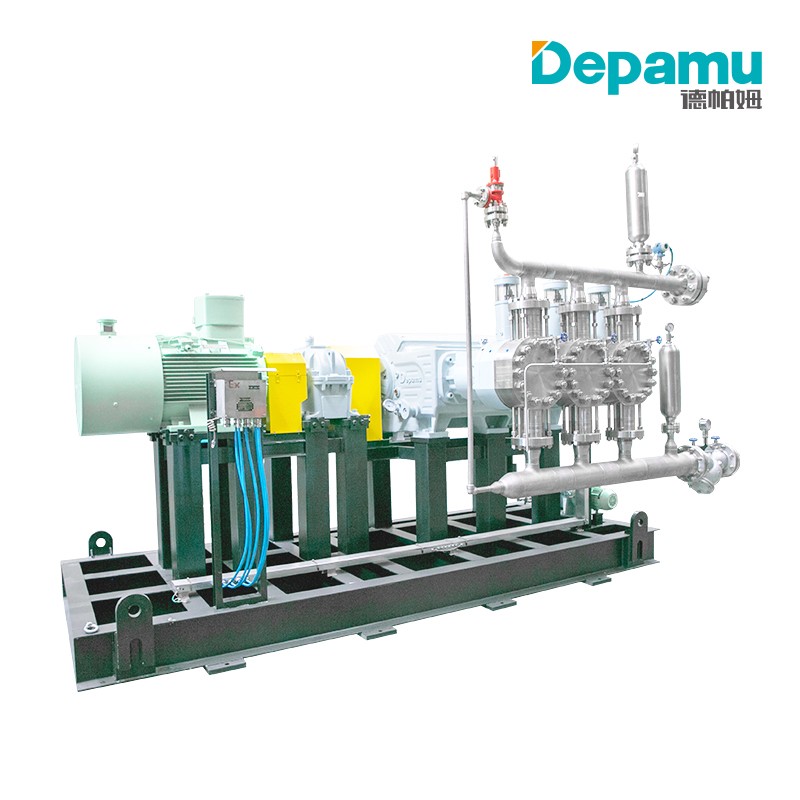

- Features of External Reducer DriveFlexible and variable reduction ratio to match different pump speeds; Flexible layout with a horizontal parallel shaft reducer, horizontal intersecting shaft reducer, vertical reducer, etc. to make full use of site space; Isolation via reduction mechanism and buffering via coupling to reduce impact of pump reciprocating and cyclic load on motor; Simplified drive end structure, reduced temperature rise and simplified pump maintenance; Lowered adverse effects of high pump crankshaft load on reduction mechanism.

- Features of Internal Worm Gear DriveHigh integration with motor mounted on the top of pump casing, pump casing anchor bolts as the only component of the whole pump contacting with foundation, rendering convenient pump installation; Big single-stage reduction ratio, compact structure, small pump footprint; Stable transmission, low noise and vibration.

- Features of External Pulley DriveSimple structure, easy mounting, maintenance and adjustment; Belt elasticity to absorb pump load impact to ensure stable pump operation with low vibration; Certain overload protection to avoid motor burning due to belt slip under overload as a result of pump overload; Low maintenance and operation cost, especially suitable for long-term unattended application.

- Features of Internal Double Helical Gear DriveSelf-alignment double helical gear drive with no axial force, stable-running crankshaft without displacement, and durable bearing; Helical gear drive with high meshing coefficient, high torque, uniform power transmission ensures small impact on gear teeth and low noise during pump operation; Reduction mechanism integrated in pump casing renders high compactness and integration, thus lowering the footprint; Direct drive by double helical gear shortening power transmission link and reducing loss, to achieve a higher pump efficiency; Power input shaft directly connected with lubricating oil pump and motor with an additional motor not required under forced lubrication.

High-pressure process diaphragm pump featuring no fluid leak due to fully-enclosed fluid chamber in liquid end is highly suitable for transfer of fluids involving severe conditions as well as toxic, hazardous, flammable and abrasive fluids in various fields, such as fuel oil, liquid ammonia, ethylene oxide (EO), etc.