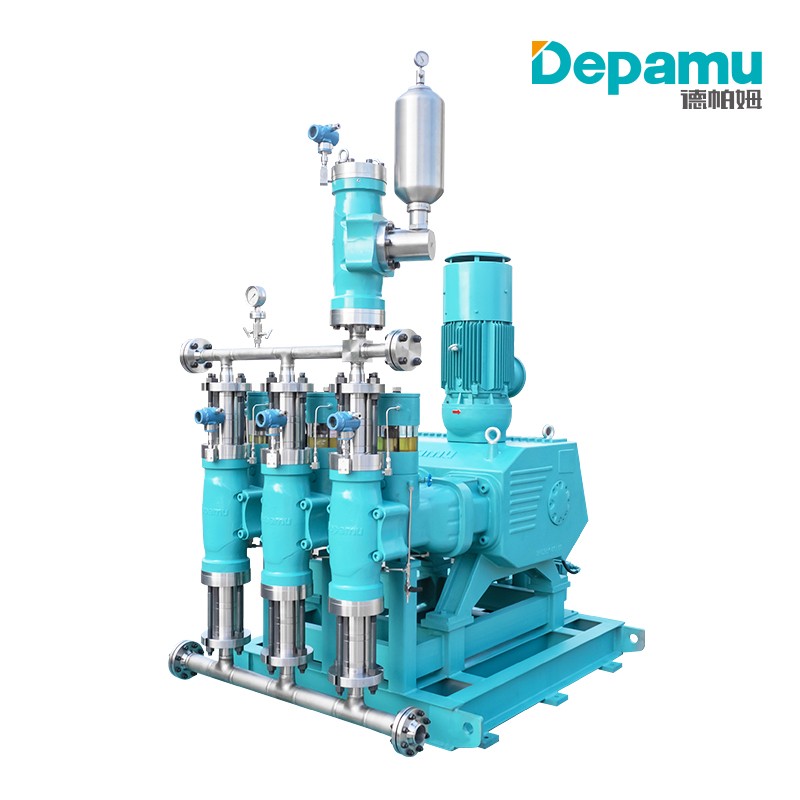

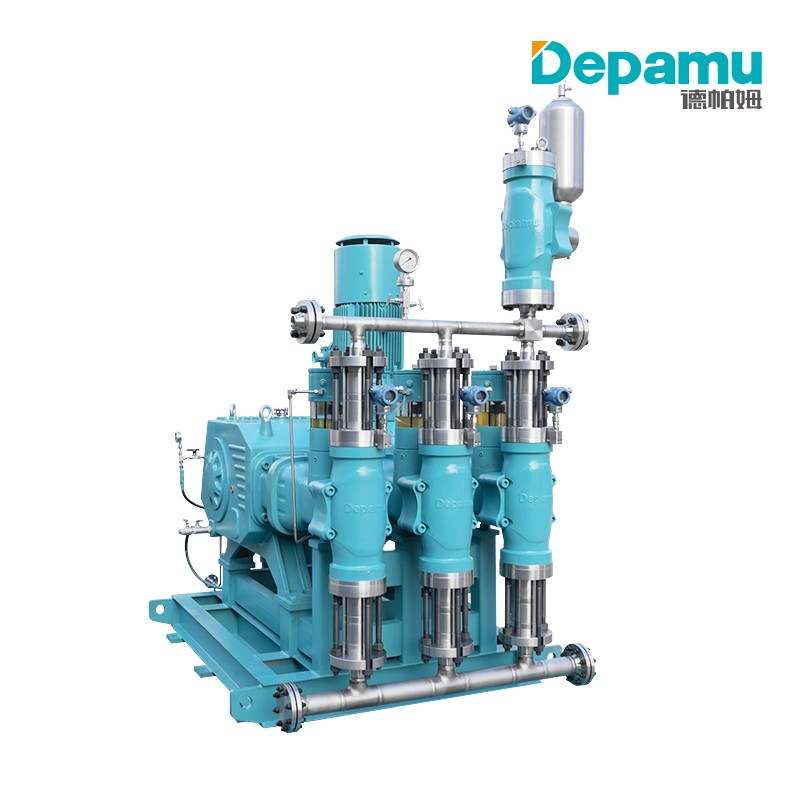

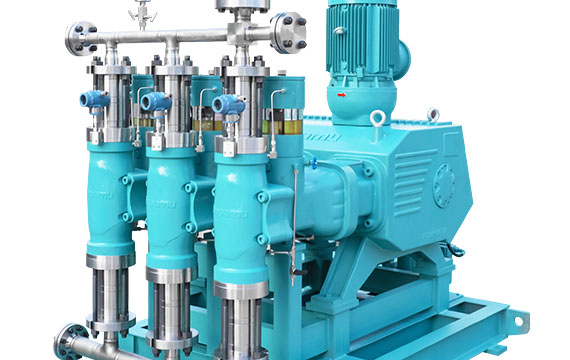

High Pressure Process Hose Pump 3HD95K-GSBD10-3.5

Wide application to industries like petrochemical, coal chemical, lithium battery, new material, mining, metal lurgy, energy, environmental protection, pharmacy, etc.,especially suitable for delivery of highly viscous fluids with particles.

Outstanding structural design

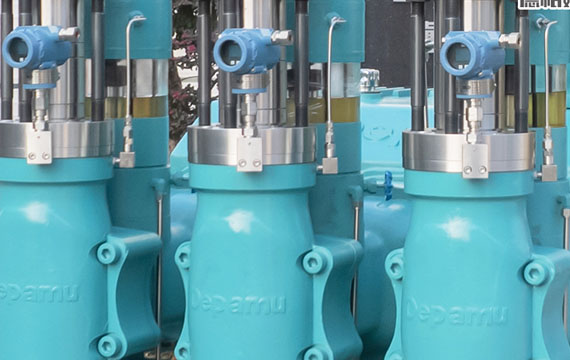

Especially suitable for delivery of highly viscous fluids with particles based on direct-through wetted end and pump head cavity without any untouched part;

Roller bearing used in connecting rod, allowable running at a low speed (rated speed<60 r/min), low linear speed of piston, fluid cavitation unlikely to happen;

Large capacity, low pulsation

Avoided contact of fluid with pump head under separation by hose diaphragm, no wearing and no leaking;Modular design and inlet and outlet valve jacket design, which facilitate maintenance;Large capacity, low pulsation and high discharge pressure;

Alarm function

Real-time detection of operation status with hose diaphragm rupture alarm function;

Automatic/manual draining control system realizes fast equipment draining and oil make-up, render- ing convenient and time-saving operation.

- Data sheet

| Capacity | 2.74-32.14m³/h; |

| Pumping Temperature | ≤ 120℃ |

| Discharge Pressure | 22-41.6MPa |

| Fluid Viscosity | < 1500cP |

| Fluid Solid Content | ≤ 80% |

Complete Guide

High Pressure Process Hose Pump 3HD95K-GSBD10-3.5

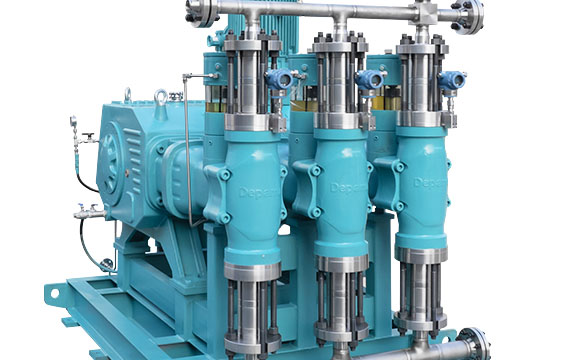

Working principle, The driver drives the crankshaft after speed reduction and torque increase in the reducing mechanism, the crank connecting rod mechanism converts rotary motion of crankshaft to reciprocating motion of piston, which pushes hydraulic oil in hydraulic chamber. Hydraulic oil transmits piston thrust force and volumetric change, acting on hose diaphragm. Hose diaphragm is subject to cyclical squeezing under force transmitted by hydrau- lic oil, leading to cyclical compression and relaxation of internal fluid chamber in hose diaphragm, thus produc- ing volumetric change. Continuous fluid delivery is realized under combined action of inlet and outlet check valve assemblies.

304, 316, 316L, 2Cr13, duplex stainless steel, Ti alloy and other metals available for choice of wetted parts material while NBR, HNBR, EPCM, FKM, etc. for that of hose diaphragm material.

Wide application to industries like petrochemical, coal chemical, lithium battery, new material, mining, metal- lurgy, energy, environmental protection, pharmacy, etc., especially suitable for delivery of highly viscous fluids with particles.

- Discharge pipeline of a high-pressure process hose diaphragm pump can be equipped with a combined hose-bladder pulsation damper, specially developed for transport of fluid with particles, high solid content and high viscosity. The unique construction of the damper can separate fluid with bladder and other structures of the damper, ensuring long-term stable operation of the damper.

- Wetted parts of a combined pulsation damper has a construction same with that of pump head for a hose pump, separating fluid with other structures of the damper. Direct-through hose construc- tion ensures no fluid deposition or precipitation and guarantees permanently stable effect of pulsation suppression.

- Fluid discharge pipeline pulsation is transmitted via hose diaphragm and hydraulic oil to bladder pulsation damper for absorption, thus realizing suppression of discharge pipeline capacity pulsation. The bladder pulsation damper keeps operating in hydraulic oil, makes no contact with fluid, and can stably operate for a long term without wearing or leaking.

- Quick-release check valve assembly allows easy replacement without removal of pipeline or pump head.

- Double-check-valve assemblies for pump inlet and outlet, avoid accidental obstruction by large-size particles in fluid during operation under single valve assembly, causing capacity fluctuation;

- Check valve with a buffer structure. Soft buffer pad fitted at valve seat can reduce impact of valve ball drop and efficiently reduce noise.

Oil make-up, air vent, limit and pressure relief system fitted inside a hose diaphragm pump, matching with all controlling components, can realize automatic intelligent control of hydraulic oil in hydraulic chamber, maintain its constant level, and ensure a stable discharge capacity during long-term pump operation.

Connecting rod and main shaft are connected via a roller bearing, featuring a small friction coefficient, low heat emission, sufficient lubrication and high bearing capacity.