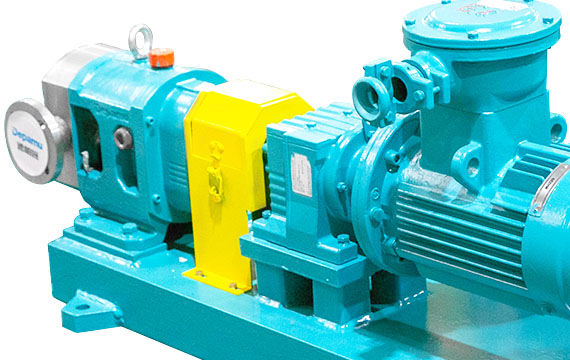

Metal Rotor Pump CLZ25DF0.3-2

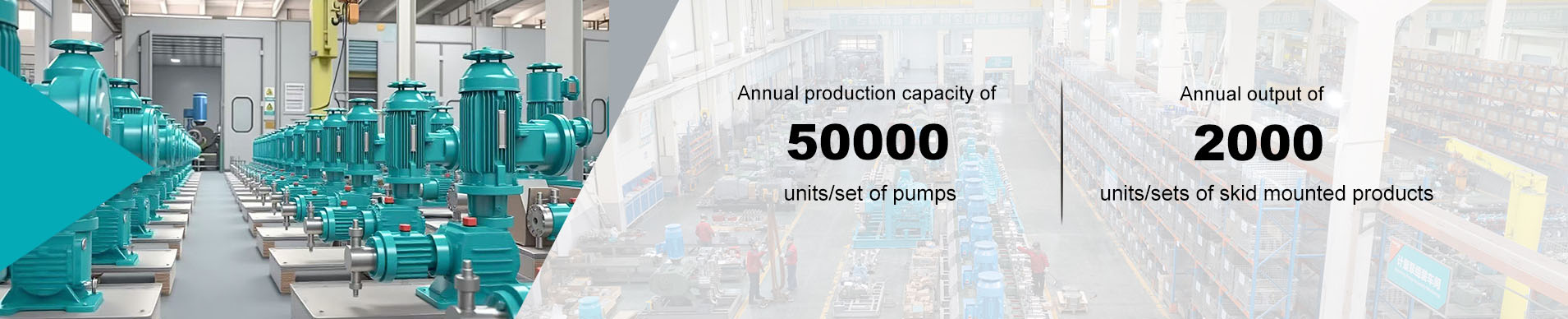

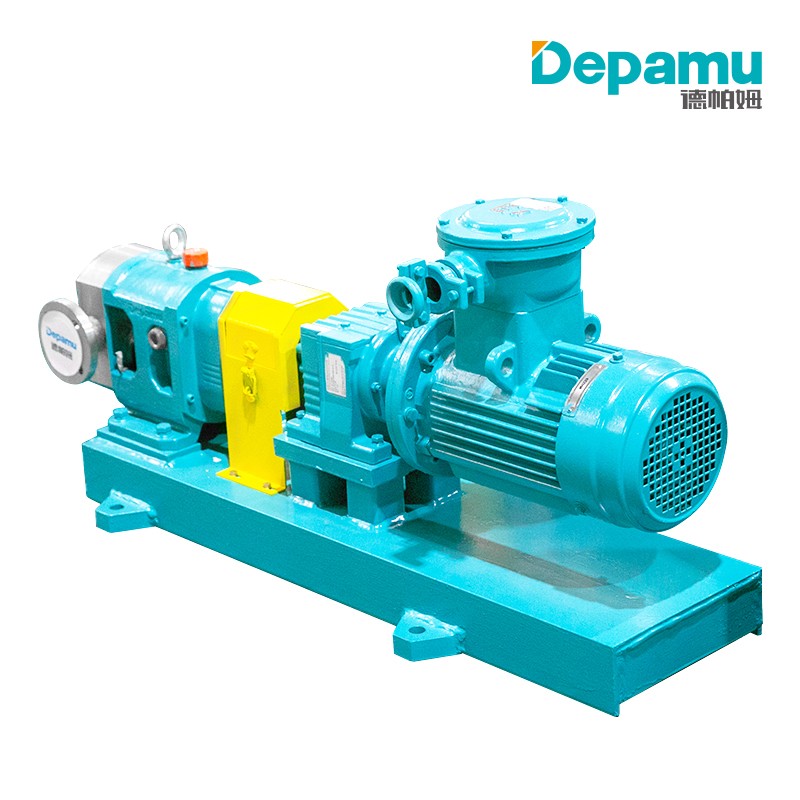

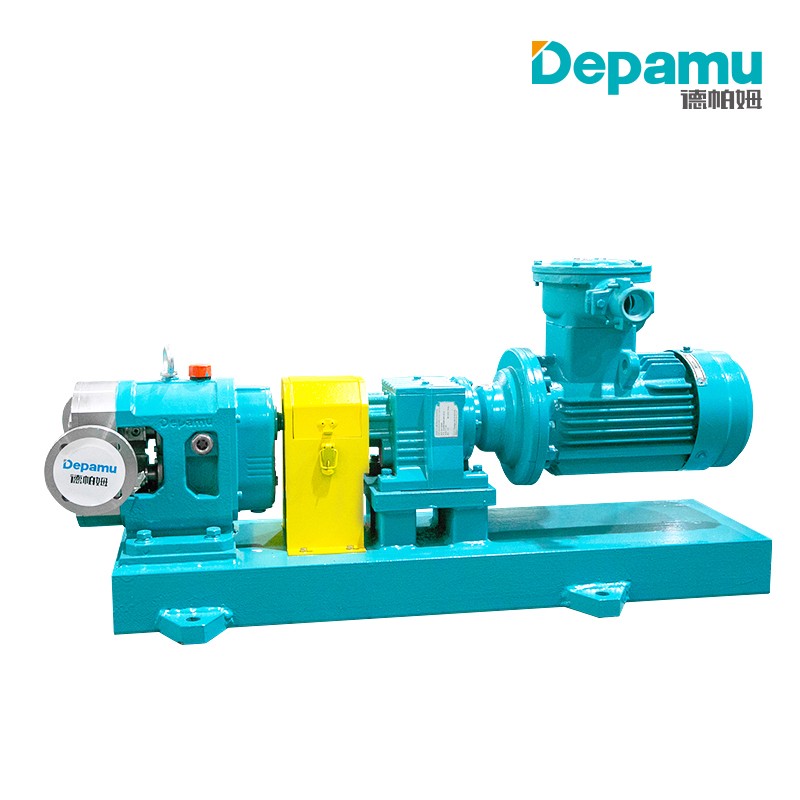

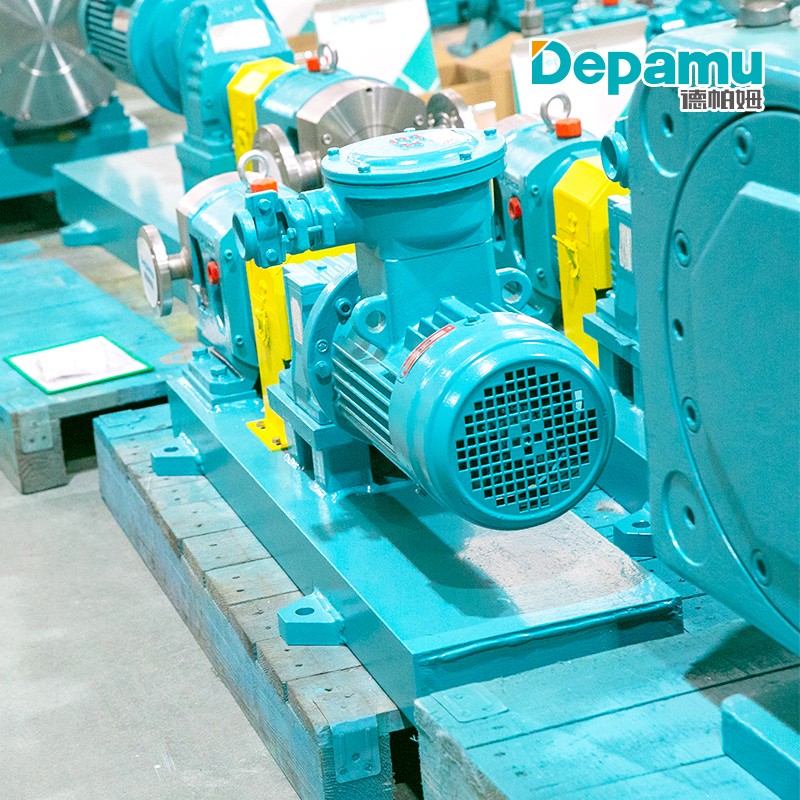

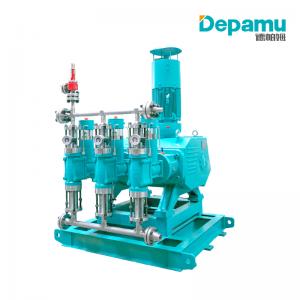

Depamu rotor pumps, stars among displacement pumps, are designed as per API 676. With a compact structure and a small mounting space, lobe pumps are widely applied to working conditions in multiple industries. With various options for rotor materials and pump mounting types, they can better satisfy actual customer demands. Besides, thanks to the completely symmetric structure, a simple change in

Modular Design

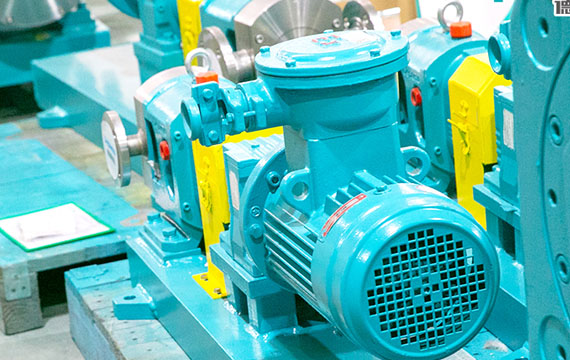

Every Depamu rotor pump adopts the design of integral pump body and gear cavity, realizing low maintenance cost and long service life.

Simple compact structure and beautiful appearance,Stableand reliable running,long service life

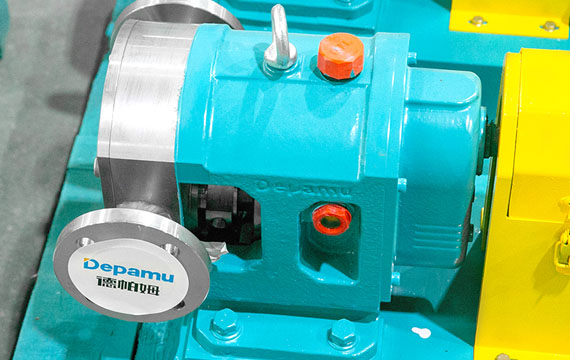

Online Maintenance

Online maintenance means all wearing parts can be easily replaced at site by an operator without the need in dismantling of any pipeline or driver.

Easy-open pump cover makes simple servicing of internal pump body. Wetted parts can be checked or replaced by pump cover opening without the need in dismantling of any pipeline or driver.

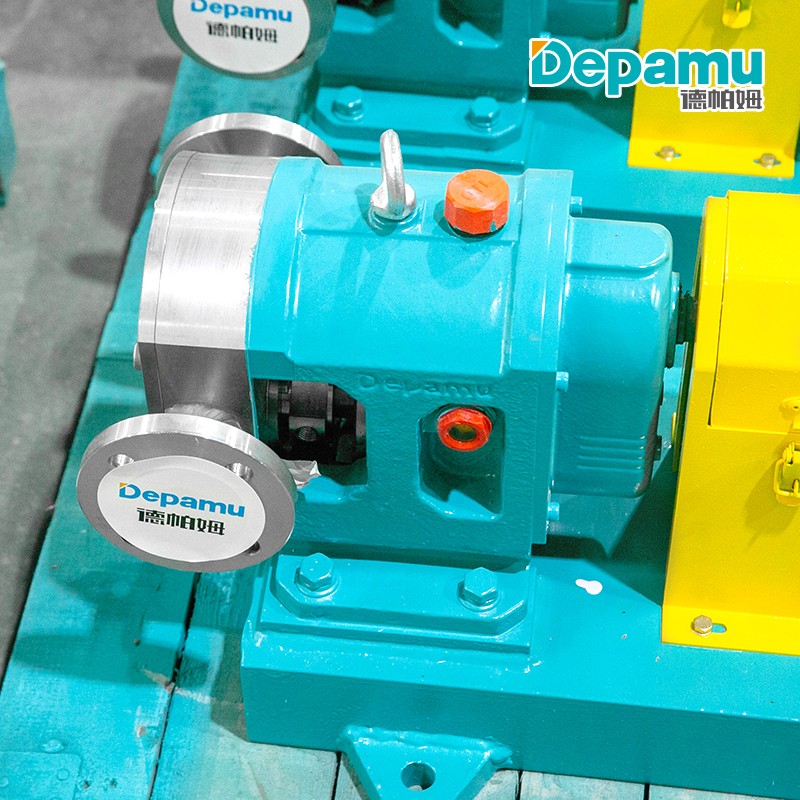

Unique patented products with replaceable rotor tips

Low noise, high efficiency, convenientmaintenance and easy replacement of wearing parts,Large seal chamber fit for various mecha nical seals;Constant capacity to delivery any fluid

- Data sheet

| capacity range | 0.1~10000m³/h |

| temperature range | 40℃~280℃ |

| maximum discharge pressure | 2.0MPa |

Complete Guide

Metal Rotor Pump CLZ25DF0.3-2

Working principle,Depamu metal rotor pumps are positive displacement pumps and the working principle is: metal rotorrotatesin circumferential flow channel within pump cavity,relative movement of rotorand pump body changes working volume, bthus increasing energy of fluid transported. On the contact side of rotor and fluid transported, energy directly acts on fluid in the form of static pressure, fluid is discharged due to extrusion of rotating rotor; at the same time, space is reserved on the other side to form low pressure for continuous fluid suction. 0.05~0.3mm clearance is reserved between two rotors and between rotor and pump body (as per transported luid viscosity, characteristics, etc.), surface tension of liquid makes up for clearance leaking, mechanical seal is made of material resistive to dry wearing and with performance resistive to idling.

Every Depamu rotor pump adopts the design of integral pump body and gear cavity, realizing low maintenance cost and long service life.

Depamu has continuously perfected lobe pump design following the conceptof reduced maintenance time and cost and developed pumps integrating powerful functions, reliable performance, stable operation and easy maintenance.

All spares and wearing parts are very durable with along service life and high cost effectiveness.

Online maintenance means all wearing parts can be easily replaced at site by an operator without the need in dismantling of any pipeline or driver.

Easy-open pump cover makes simple servicing of internal pump body. Wetted parts can be checked or replaced by pump cover opening without the need in dismantling of any pipeline or driver.

Inlet and Outlet FormVarious inlet and outlet forms can be ascertained as per site working conditions and technologies; besides,a flood drain pump truck assembly has multiple drainage inlets and outlets. Installation TypeConcentric Installation Way of Integrated Gearbox; Concentric Installation Way of Separate Reduction Motor;Installation Way of Easy and Portable Trailer;Vertical Installation of Reduction Motor

- Simple compact structure and beautiful appearance

- Stableand reliable running,long service life

- Low noise, high efficiency, convenientmaintenance and easy replacement of wearing parts

- Unique patented products with replaceable rotor tips

- Large seal chamber fit for various mecha nical seals

- Constant capacity to delivery any fluid

- One-blade RotorSuitable for transport fluid with large particles; its unique shape and curve effectively avoid damage of particles in fluid during transport; be noted that discharge flow contains high pulsation and pressure is low.

- Butterfly RotorSuitable for transport stuffing with medium-small particles, rendering low breakage percentage and low pulsation of discharge flow.

- Three-blade RotorThe type of the highest universality offering a displacement bigger than that of all rest rotors and a certain breakage percentage of fluid with particles

- Multiple-blade RotorWith increase in the quantity of rotor blades, displacement decreases gradually while pumped fluid stability increases, the rotor renders high breakage percentage offluid.

- Daily-use Chemical IndustryAES, LAS, MES, K12, glycerol, sorbitol,fatty alcohol, shower gel, skin cream, shampoo, hand sanitizer, toothpaste, soap,washing powder slurry,etc.

- Fine Chemical IndustryDyestuff, pigment, pulp, chemical additive, adhesive, 107 glue, silicone oil, leather oil, colloidal material, etc.

- Food IndustryChocolate, concentrated milk, yogurt, honey, syrup, cane sugar, tomato ketchup, concentrated juice, jam, ice cream, milk, yeast slurry, meat sauce, jelly, condiment, alcohol, soybean protein, flour, edible oil, etc.

- Pharmaceutical IndustryOintment, medicine latex, pill paste, syrup, health care product, donkey hide gelatin, drug, amino acid, etc.

- Paper-making IndustryCalcium carbonate, starch paste, PAM,carboxyl starch paste, rosin size, rosin, paper pulp, filling, dry strength agent, wet strength agent, sizing agent, filtering agent, defoamer, coating and water treatment chemical.

- Chemical Fiber IndustryPectic slurry, PVA, vinylon slurry, acrylic slurry, ammonia slurry, polyester slice, terylene slurry, polypropylene slurry, rayon slurry, functional fiber slurry, etc.

- Coating IndustryPaint, dope, printing ink, insulating paint, resin, additive and assistant, organic solvent, etc.