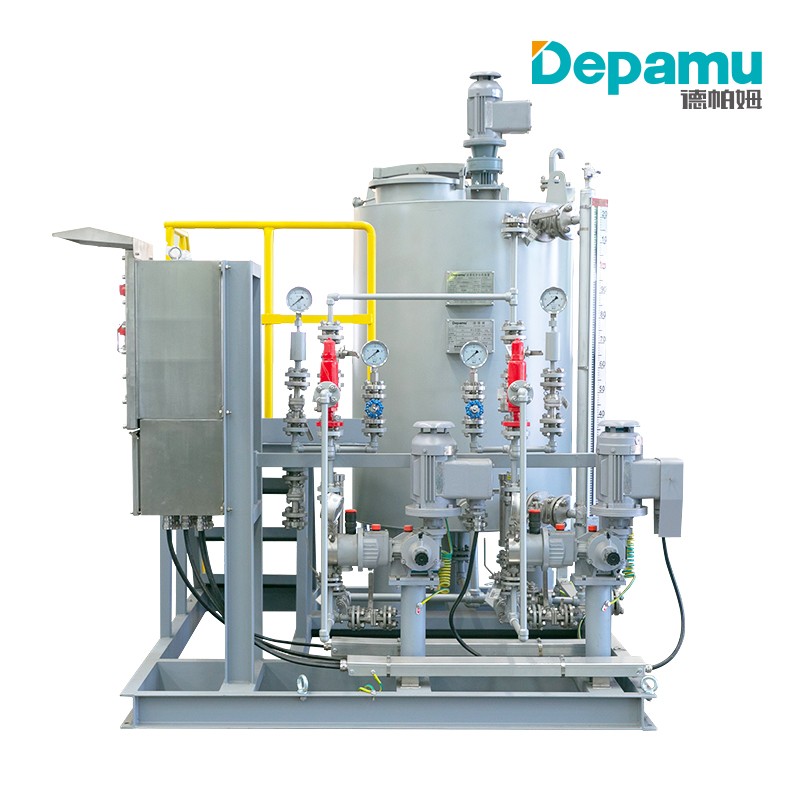

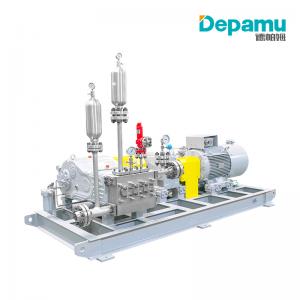

Injection Package DPJY-1.0X1-DPMSWAB37-5.5-IX2

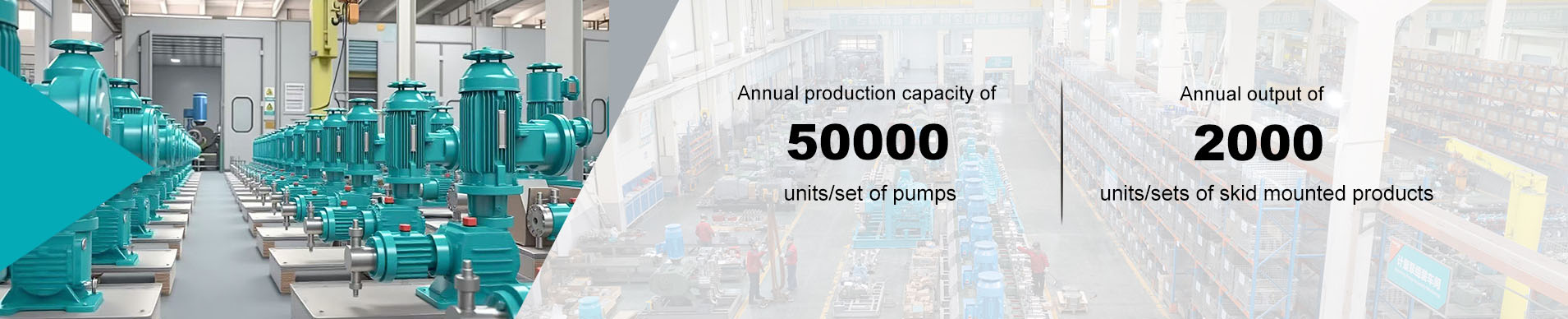

DPJY-series injection packages are complete sets of equipment manufactured by Depamu through research and development strictly following process

Automatic Control System Function

Under the state of automatic control, through signal processing of flow rate, PH value and phosphate radical value via PLC, host computer or DCS, the system can automatically adjust the rotation speed and the stroke of a metering pump, and it allow sametering pump flow adjustment range at 0~100%.

The frequency control input signal of the frequency converter is a standard 4~2mA signal, same with the feedback signal. Under demand, all signals for metering pump and mixer state and fault can be transmitted to DCSor host computer, which can remotely start or stop the injection pump as required.

Cabinet control

According to different technical requirements, an electrical control cabinet can be controlled locally and manually, semi-automatically or automatically.

316 or 304 stainless steel

A solution tank can be made of 316 or 304 stainless steel according to differentanti-corrosion requirements.

- Data sheet

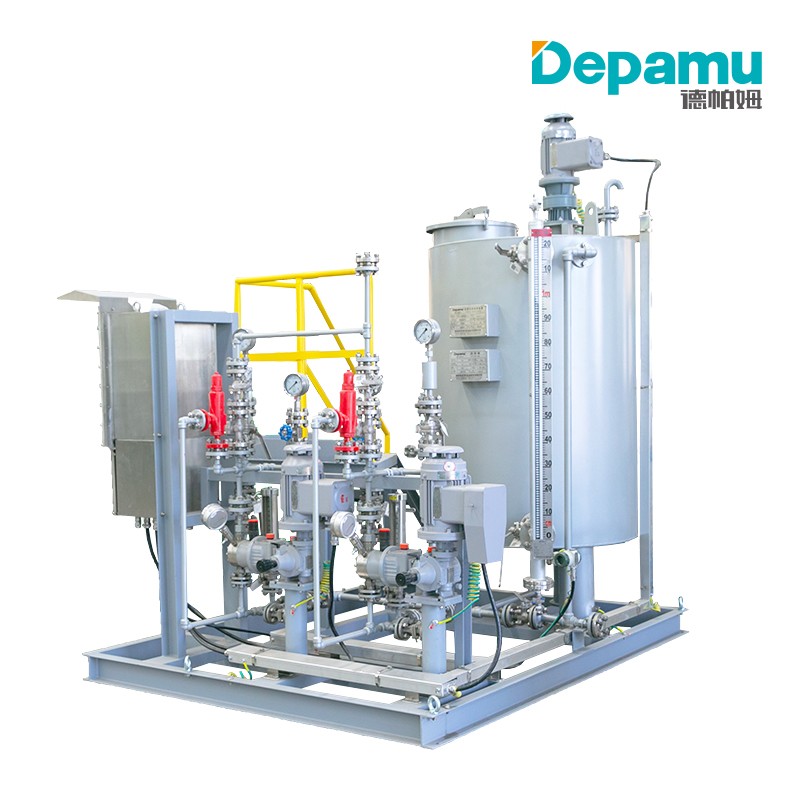

| Capacity | 2.74-32.14m³/h; |

| Pumping Temperature | ≤ 120℃ |

| Discharge Pressure | 22-41.6MPa |

| Fluid Viscosity | < 1500cP |

| Fluid Solid Content | ≤ 80% |

Complete Guide

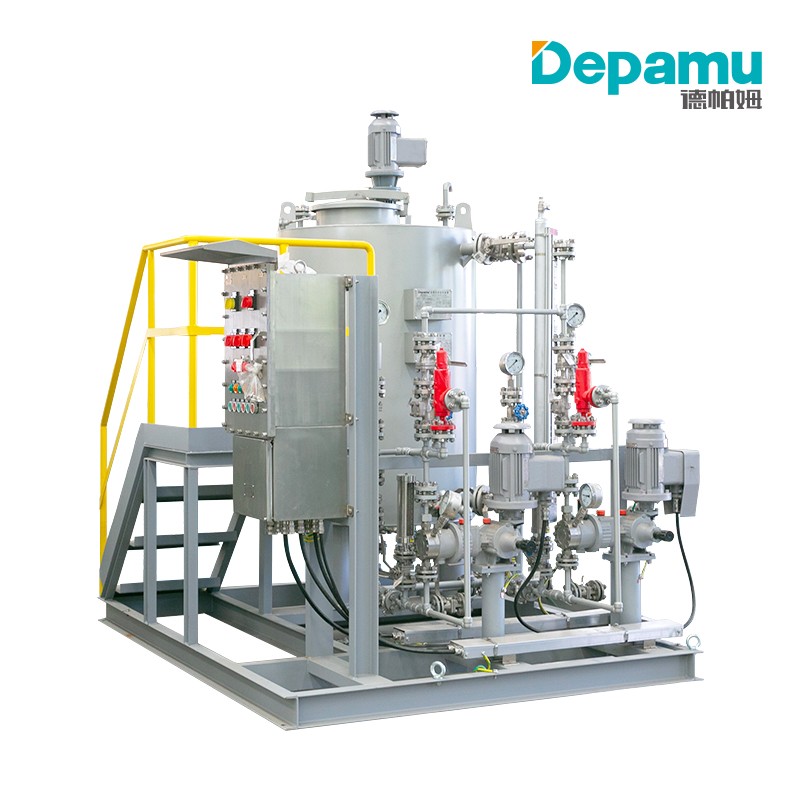

Injection Package DPJY-2.0X1-DPMSWABK12-9.2-IIIX2

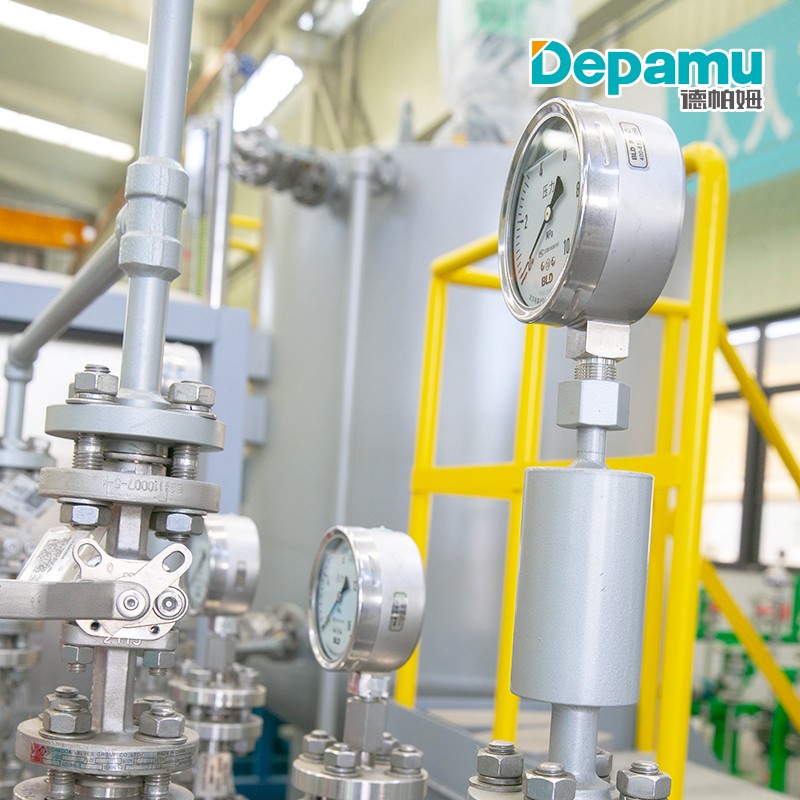

Process Overview, Phosphate injection packages, composed of solution tank, metering pump,electrical control cabinet, level gauge, safety valve, pulsation damper, all kinds of valves, pipes, etc., can be controlled locally and manually or automatically. Automatic control is realized based on frequency converter's reception of signals for flow rate, PH value, phosphate radical value,etc.

Boiler water injection package, circulating water injection package, raw water pretreatment injection package, wastewater treatment injection package, sewage treatment injection package, chemical additive injection package for oil field and gas field, etc.

DPJY-series injection packages, applicable to boiler feed water treatment, boiler water treatment, circulating water treatment, raw water pretreatment, sewage treatment and petroleum chemical industry, can be used for quantitative transportation of chemicals and to meet process requirements arising from different operating conditions.

A complete-set device, composed of solution tank, metering pump, level gauge, safety valve, pulsation damper, all kinds of valves, pipes, electrical control cabinet, etc. installed on one iron base, is an integral combination achieving functions of chemical dissolving, preparation, metering and injection, and featuring a compact structure, a small size, easy transportation and installation. It can also be designed into various shapes based on dosing room space requirements of users.

Metering pumps included in the device can be randomly used as working or standby pumps; in case of two or more solution tanks, the tanks can be separately used alternately through valve switching or be used simultaneously. 1.According to different anti-corrosion requirements, a solution tank can be made of 316 or 304 stainless steel, carbon steel, carbon steel with rubber (plastic) lining, FRP, PE, PVC, etc. 2.According to different anti-corrosion requirements, wetted parts can be made of 316 or 304 stainless steel, carbon steel, UPVC, etc.

Existence of calcium and magnesium hardness in boiler feed water will lead to chemical reaction in a high-temperature environment or concentration and crystallization, thus generating scale firmly attached to the heated surface of the boiler. Scale formed, a poor conductor of heat, will block heat conduction and may result in boiler tube explosion when scaling situation becomes serious. Moreover, it will trigger and intensify chemical corrosion of metal covered by scale, causing great harm. Despite strict softening and desalting treatment of boiler condensation water and feed water, a little calcium and magnesium ions enter in boiler water; if no treatment is done for such hardness, scaling arises, posing a threat to safe boiler operation. At present, the most appropriate treatment method is phosphate injection in boiler water and the chemical reaction equation is provided below: 10Ca2++6PO43-+2OH-=Ca10(OH)2(PO4)6 (Hydroxyapatite) Hydroxyapatite, loose and soft water slag, can easily be eliminated through boiler blowdown, won't adhere to the inside face of the boiler or become scale afterwards.

- Adoption of systematic design avoids systematic differences existing in traditional products under single-equipment or single-part design;

- Brand-new design concepts based on absorption of the essence in domestic and foreign dosing technologies make our techniques more reasonable;

- Modular design of product structure in an integrated combination allows for convenient extension in aspects of capacity and function;

- A best solution can be provided flexibly according to different medium and user demand;

- A user can randomly select equipment and parts of famous domestic and foreign brands in various materials at alllevels;

- Multiple control modes like manual mode, automatic mode, etc. can be selected to meet all kinds of control requirements.