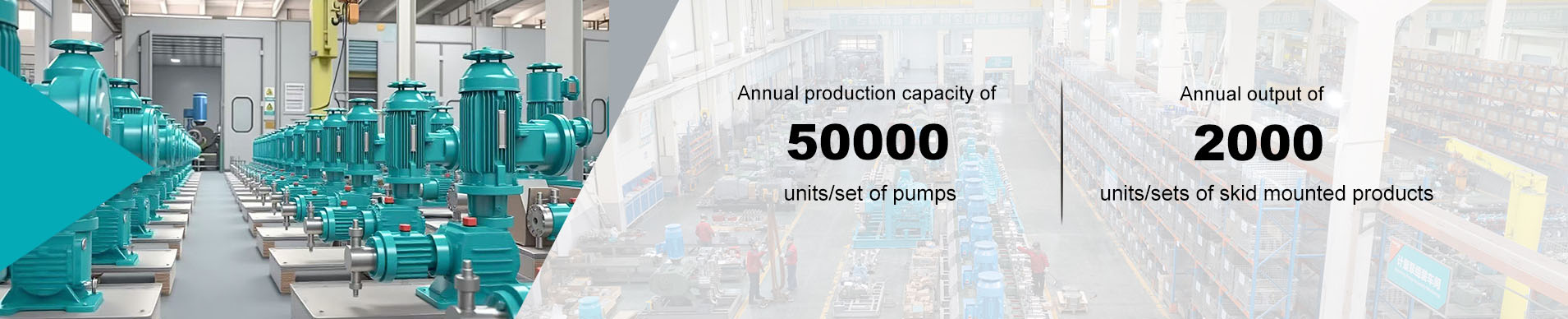

DoubleScrew Pump CLWXB102-56

Based on advanced German technologies and professional technology certification,Depamu single screw pumps show obvious superiority in terms of special working conditions like fluids with a high viscosity, containing hard suspended particles, etc. featuring a long service life and reliable operation with many patents held of the first-rank international level.

Stable fluid transfer without stirring or pulsation

strong self-priming capability since pumped fluid always exists in pump working components as sealing liquid; allowable mixed transfer of oil and gas with a max. gas content at 98%;

Special design ensures strong suction capability with 1.5m NPSH;

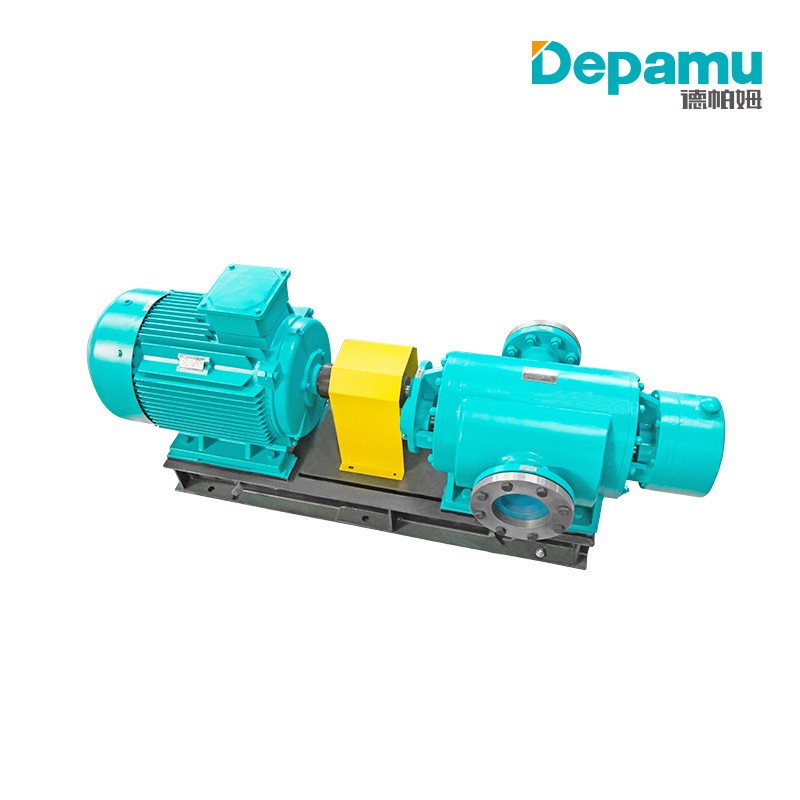

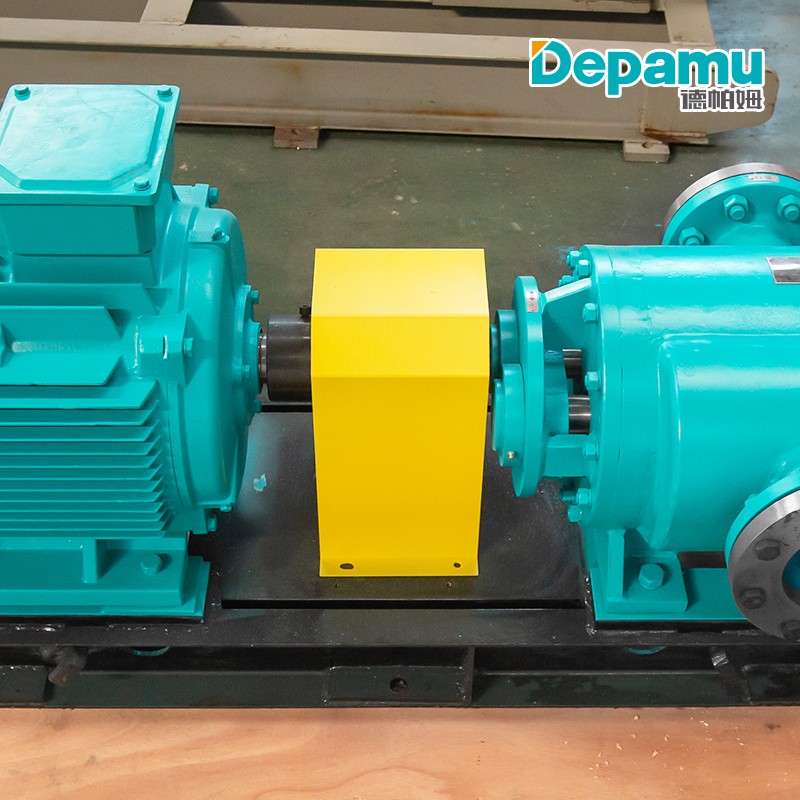

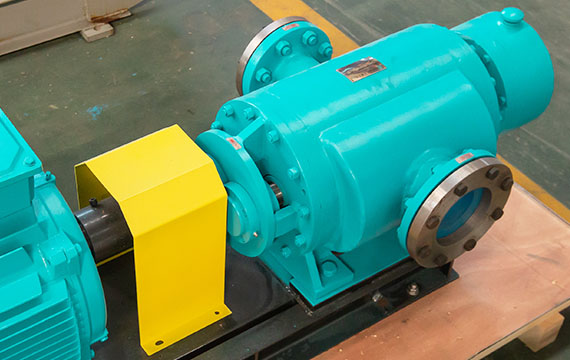

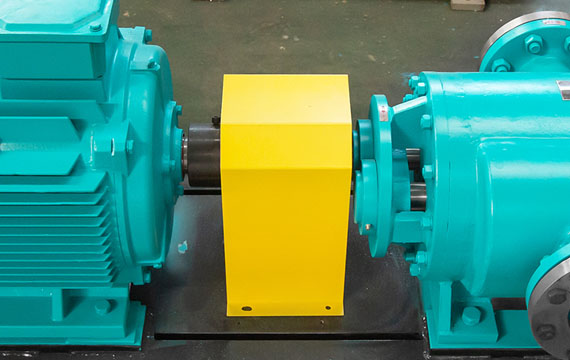

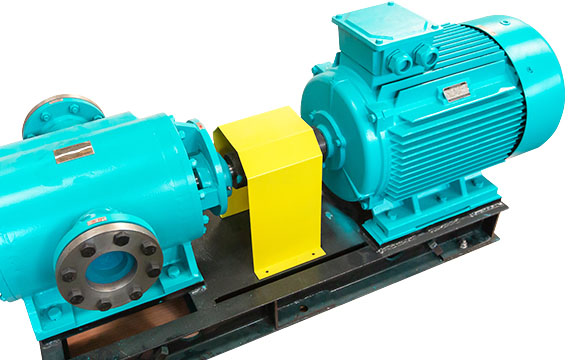

External bearing &Synchronous gear transmission

Mounting of external bearing with separate lubrication makes possible transfer of non-lubricating fluids;

Synchronous gear transmission with no contact among rotating parts avoids danger during short-period dry pump running;

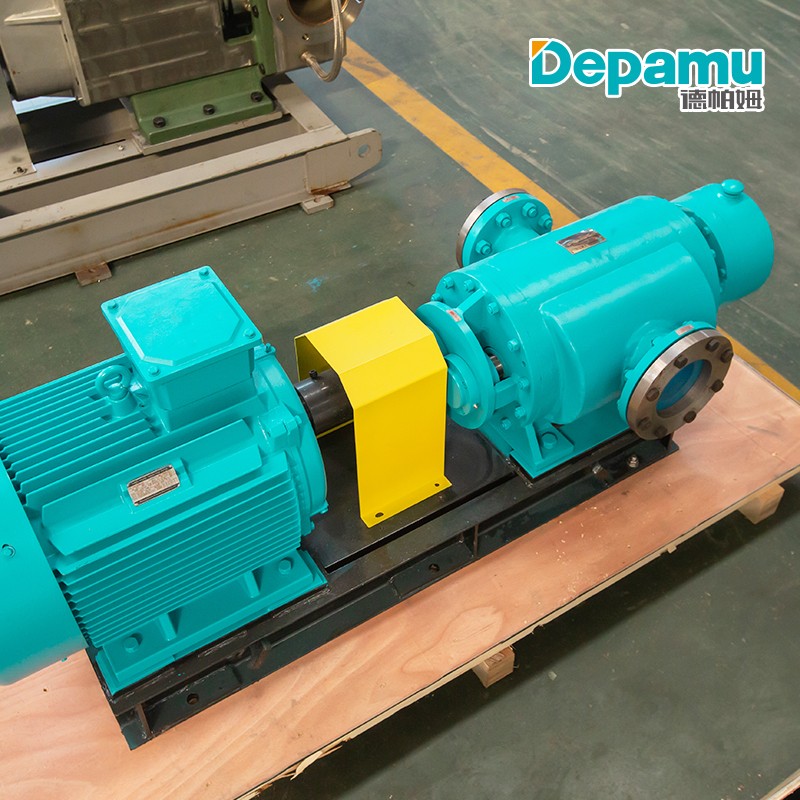

Heating jacket installation

Pumps in different structures are applicable to different conditions;Under highly viscous fluid transfer, heating jacket can be installed at pump bottom.

- Data sheet

- Specification

| Fluid Viscosity | 1.5×106Cst |

| Temperature | -20℃~350℃ |

| Pressure | 1~6.3MPa |

| Max. Speed | 1800rpm |

| Capacity | 0-2000m3/h |

Complete Guide

DoubleScrew Pump CLWXB102-56

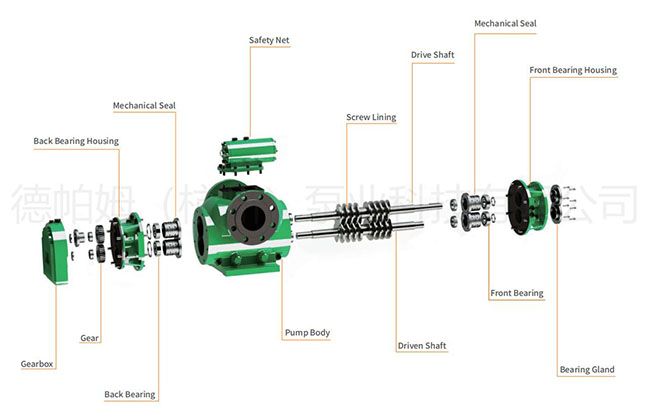

Working principle, As a type of constant displacement pump, screws in a pump mesh, spiral grooves on screws and hole-walls accommodating screws form interconnecting enclosed cavities, which axially move forward continuously and stably without stirring along with continuous rotation of screw pump, thus realizing transfer.

Double screw pumps are applicable to transfer of fluids with a low/high viscosity, lubricating or non-lubricating fluids, corrosive or non-corrosive fluids as well as mixed transfer of multi-phases containing gas.

During operation, sealed cavities are formed between two screws as well as between screws and lining holes, liquid flows into pump through inlet, enters sealed cavities and is transferred stably to outlet. Lining holes are provided with locating spigot and screw shaft is provided with locating bearing, contact is avoided during pump operation between two screws as well as between screws and lining holes. Various liquids can be transferred (like non-Newtonian fluid, lubricating liquid, non-lubricating liquid, etc.). Due to special design of inlet flow passage and a relatively low axial liquid speed during pump operation, NPSHr is small and pump self-priming capability is strong. Bearing and synchronous gear are lubricated by gear oil in gearbox.

Connecting screws of pump body can be removed easily for cleaning of pump body, screw bushing and mechanical seal; wetted parts of pump can be thoroughly cleaned without any space left; cleaning or sterilizing can be made with steam or other fluid below 180℃; internal safety valve is provided.

- Petroleum and Petrochemical Light and heavy oil, acid, alkali and salt solution, viscous chemical paste, emulsion and slurry, oil-water separation and waste oil recovery system, polymer transfer.

- Environmental ProtectionIndustrial and domestic sewage treatment, oily water treatment, transfer of sludge and muddy water with solid particle and short fiber, oil-water separation and waste gas engineering, metering and dosing of flocculant and chemical agent.

- Exploitation and MiningTransfer of drilling mud, mining water supply and drainage, mining duster water supply, preparation, loading and grouting of mortar, concrete, titanium dioxide and kaolin sprayed on mine laneway wall.

- Medicine and FoodTransfer of medical ointment, syrup, jam, fermentation broth, honey, cream, starch paste, toothpaste, etc.

- Shipping Industry Bilge cleaning pump, marine incinerator transfer pump, oil-water separator pump, transfer of engine room oily water, etc.

- Energy IndustryTransfer of fuel oil, coal water slurry, resin and additive

- Paper-making Industry Transfer of paper pulp and short fiber slurry, slurry and waste water treatment, chemical metering, raw material preparation, coating and coloring process

- Building IndustryPaste transfer like cement mortar, painting, lime milk, etc.

- Electrolyte TreatmentTransfer of paste, emulsion, suspension as well as fluid requiring no stirring or shearing.

- Mechanical Engineering Oil-water mixture, sludge with metal, metallurgy slurry and waste tank emptying.

- Pump core in component-based design rendering convenience in repairing and part replacement;

- Torque transmission via synchronous gear ensuring low noise;

- Radial sliding bearing with a long service life;

- Balanced pump structure ensuring no axial force on screws and a long service life;

- Merely one set of mechanical seal provided to reduce the quantity of leaking points and lower maintenance cost;

- Simple structure, small size and light weight ensuring easy mounting and maintenance.