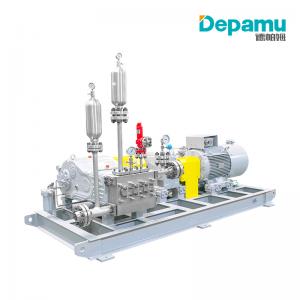

Hydraulic Diaphragm Metering Pump DPMWAAB55-5

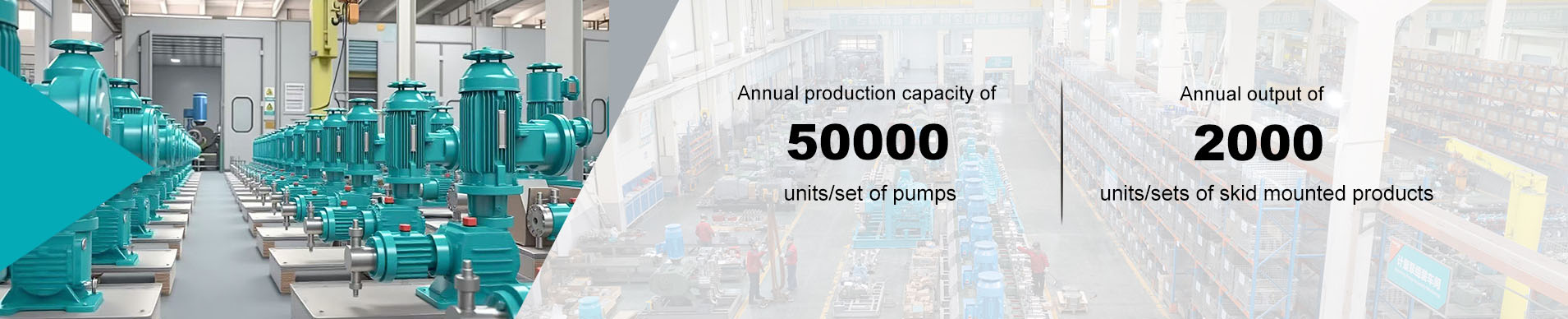

Depamu metering pumps, a kind of reciprocating pumps evenly and stably transporting liquid in a measurable quantity, are widely applied to industries like petroleum, natural gas, chemical, electricity, environment, protection, pharmaceutical, food, military, construction material, etc.

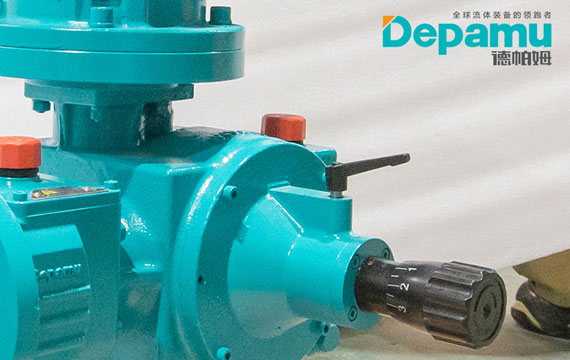

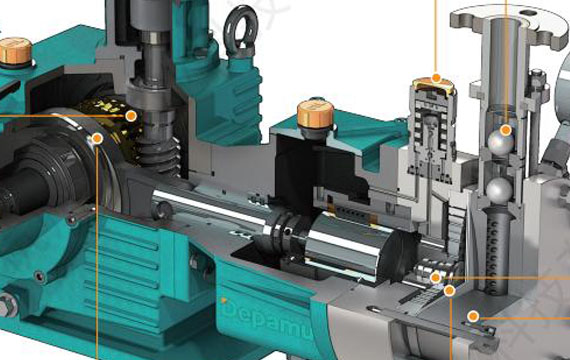

Vertical motor installation & Patented technology

Vertical motor installation ensures safety without leakage;A hydraulic diaphragm pump contains internal safety valve and compensation valve realizing automatic air discharge and oil replenishment with outstanding and reliable performance

Adoption of a patented integrated sleeve adjustable eccentric transmission mechanism, simple and reliable, and stroke can be steplessly adjusted in the range of 0%-100%;

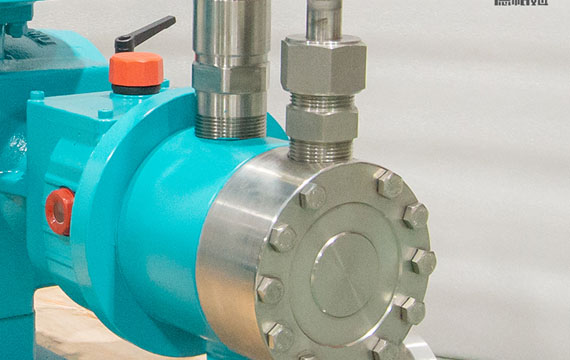

high-precision check valves & Oil-immersion ubrication

Inlet and outlet high-precision check valves can effectively guarantee metering accuracy and fluidity;High performance plunger, special imported packing, diaphragm and sealing components have a long service life and excellent sealing performance;

Oil-immersion ubrication ensures reliable use of the trans- mission mechanism for a long term;It can be used to transport a same fluid to reduce pulses or transport different fluids as a proportioning pump with inde-pendent flow adjustment of either pump head;

Different Capacity control modes

The capacity range is 10%-100% and the metering accuracy is±0.5%;Capacity control modes are diversified, including manual, electrical, pneumatic and variable frequency control.

- Data sheet

| Max Discharge Pressure | 95 MPa |

| Max Discharge Flow Rate per Pump Head | 12100 L/h |

| Flow rate can besteplessy adjusted range | 0-100% |

| Metering accouraoy reaches | ±0.5% |

| Capacity Range per Pump Head | ≤12100 L/h |

| Pressure Range | ≤70 MPa |

Complete Guide

Hydraulic Diaphragm Metering Pump DPMWAAB55-5

Working principle, Reciprocation of the plunger drives hydraulic oil, which drives the diaphragm to do reciprocation motion, thus realizing fuid suction and discharge.

Capacity Range per Pump Head: ≤12100 L/h; Pressure Range: ≤70 MPa;

A pump head can be made of 304, 316, 316L, 904, Hastelloy C, PVC, PVDF, PP, PTFE, etc.

- Adoption of automatic oil supply and internal safety protection technology based on mutual interaction of diaphragm-limit valve-compensation valve-internal safety valve. The accuracy of a limit valve reaches ±0.002mm, the surface hardness reaches 60~70HRC and the roughness reaches 0.4μm; the pump can be reused for 80 milion times within a temperature range of -80℃~160℃;

- Through multi-directional roling and surface quenching treatment, evenness of PTFE macro-molecule composite diaphragm reaches 99.92%, cold flow is reduced during operation and compressive strength is enhanced;

- Internal safety valve and compensation valve realizing automatic air discharge and oil replenishment have outstanding and reliable performance;

- Inlet and outlet high-precision check valves can effectively guarantee metering accuracy and fluidity;

- Integrated worm gear, used as a variable speed transmission mechanism, features low noise and high effciency;

- Adoption of a patented integrated sleeve adjustable eccentric transmission mechanism, simple and reliable, and stroke can be steplessly adjusted in the range of 0%-100%, the metering accuracy is ±0.5%(10%-100%adjustment range);

- Oil-immersion lubrication ensures reliable use of the transmission mechanism for a long term;

- When transporting hazardous fluids toxic, flammable, explosive or strongly corrosive, double diaphragms or multiple diaphragms can be used;

- The diaphragm rupture alarm device prevents fluids from contact with hydraulic oilin case of diaphragm rupture, thus avoiding happening of any accident;

- Capacity control modes are diversified, including manual, electrical, pneumatic and frequency conversion adjustment;

- Installation of an electric actuator ensures realization of automatic remote control;

- Two pump heads or multiple heads(12 at most)can be connected in parallel; a pump with two or more heads can be used to transport a same fluid to reduce pulses or transport different fluids as a proportioning pump;With a wide application range, it can safely transport all kinds of fluids.

- Hydraulic Double Diaphragm Alarm Pump Head A hydraulic double diaphragm alarm pump head (see Picture A), carrying all the features of a hydraulic diaphragm pump head, has a diaphragm rupture detector additionally, which can output alarm signals when one diaphragm ruptures while ensuring continuous normal working of the other diaphragm. It is mainly used to transport dangerous media flammable, explosive and toxic. Under harsh working conditions, it is suggested to use a triple-diaphragm alarm pump head (see Picture B) or quadruple-diaphragm alarm pump head (see Picture C), safer and more reliable.

- Hydraulic Metal Diaphragm Pump Head A hydraulic metal diaphragm pump head is applied to occasions of a high pressure and a high temperature. The maximum working temperature reaches 451℃ and the pressure reaches 70Mpa.

- Remote Diaphragm Pump Head A remote diaphragm pump head (see Picture D) realizes a short-distance design between suction valve and discharge valve, thus effectively reducing fuid sedimentation time; at the same time, a cooling system is installed on the transportation pipeline of check valve and pump head to avoid bad effects on pump head and mechanical transmission parts due to over-temperature. It is applicable to fluid with a high temperature, high viscosity and high toxicity or easy to precipitate as wellas occasions with special requirements of installation position.

- Hydraulic Temperature-controlled Diaphragm Pump Head A hydraulic temperature-controlled diaphragm pump head (see Picture E) is applicable to deliver fluids whose temperature needs to be controlled. Heat exchange and temperature compensation are conducted when fluid enters the pump head, ensuring correct fluid injection; besides,in case of viscous fluid transport, in order to improve liquidity, based on the principle that liquid viscosity lowers with a temperature rise, fluidity of fluid entering pump head is increased through heat exchange for the purpose of smooth transport and accurate metering. At the same time, the plunger chamber with a supporting cooling device reduces bad effects on mechanical transmission parts due to over-temperature.

- Electric Actuator An electric actuator (see Picture F)is connected with the flow adjustment screw rod of a metering pump, can change the stroke length through change in the number of rotation times via receipt of 4-20mA input signals, and output a group of 4-20mA feedback signals to form closed-loop control, finally adjust the output flow rate of the metering pump, realize remote or automatic adjustment of flow rate as well as automation. A specific stroke percentage and operation status can be displayed on the LCD screen.

- Variable Frequency Adjustment A VFD controls the rotation speed of a motor through change in the motor power frequency, thus changing the number of stroke times and adjusting the flow rate of the metering pump.

- ut labore et dolore Oil-immersion lubrication ensures reliable use of the transmission mechanism for a long term;

- Pneumatic Actuator A pneumatic actuator(see Picture G)can change direction and adjust volume of air supply via 4-20mA signal, drive adjusting screw rod via air, adjust stroke length and output 4-20mA feed signal to realize closed-loop control and achieve the purpose of automatic remote intrinsic-safety ex-proof flow adjustment. Stroke length percentage can be displayed on site mechanical scale, digitally displayed and adjusted via IP converter or displayed and controlled remotely via DCS.

It is widely used in scientific research and production departments in industries of petroleum, chemical, natural gas, food, paper-making, batomic energy technology, power plant, plastics, medicine, environmental protection, textile, mine, etc, and can be applied to transport of media strongly corrosive, easy to volatile or crystallize, flammable, explosive, toxic, stinky, with a large specific gravity, a medium viscosity or radioactivity, or other noble metal.