Mechanical Diaphragm Metering Pump DPMFXWAD90-0.3-III

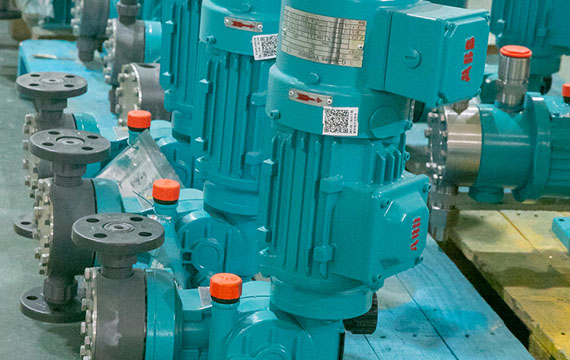

Depamu metering pumps, a kind of reciprocating pumps evenly and stably transporting liquid in a measurable quantity, are widely applied to industries like petroleum, natural gas, chemical, electricity, environment, protection, pharmaceutical, food, military, construction material, etc.

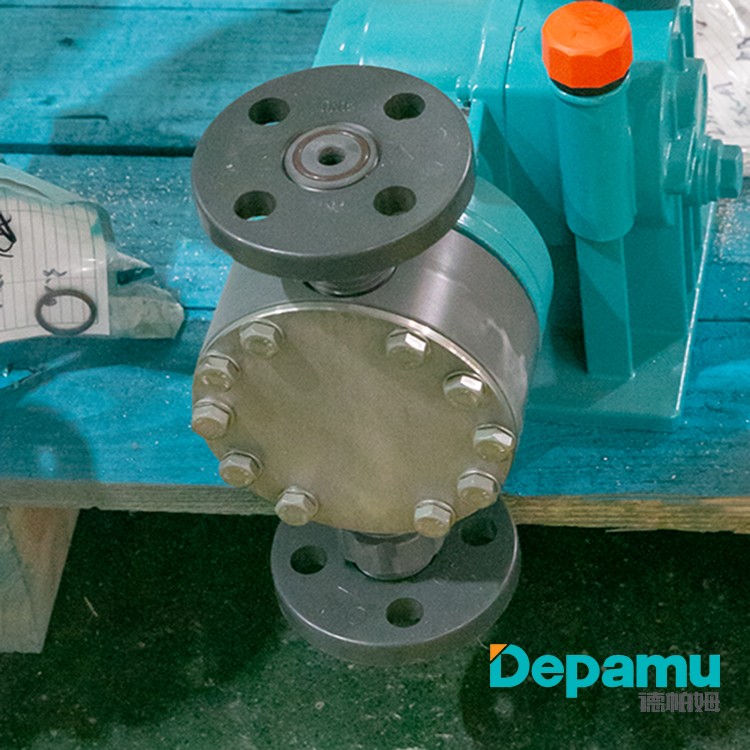

Design of single and double diaphragms & alarm system

An advanced design of single diaphragm and double diaphragms uniformly forced through grinding, making diaphragms more durable;Double PTFE diaphragms show excellent corrosion resistance and leakage prevention;

The diaphragm status monitoring system can send out signals when one diaphragm ruptures, the pump can continue working till diaphragm replacement or it can be stopped directly without any pollution to fluids;

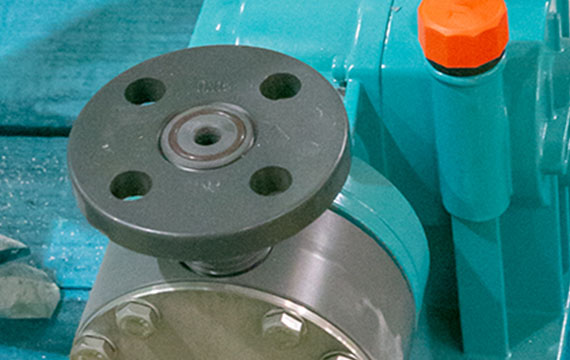

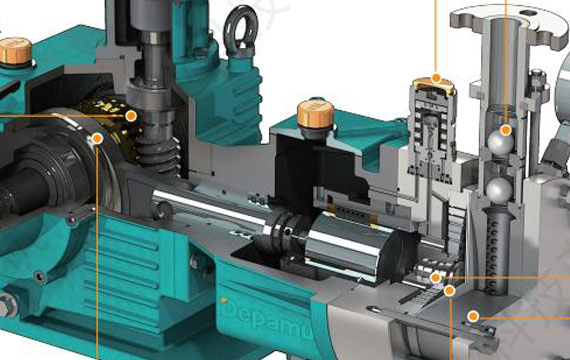

Design of eccentric mechanism & Easy maintenance

An accurate design of eccentric mechanism, including cam and spring eccentric mechanism, and integrated sleeve adjustable eccentric transmission mechanism;

Static seal of diaphragm at hydraulic end replaces dynamic seal of plunger, ensuring no leakage during fluid transportation;Diaphragm movement directly driven by the slide bar replaces cyclic reciprocation of diaphragm hydraulically driven, so the structure of a mechanical diaphragm pump is simpler and makes maintenance more convenient;

Patented design

Depamu mechanical diaphragm pumps, in a patented design, ensure a stable flow output;

Whether a pump is shut down or running, stable flow outputs can be steplessly adjusted via the fine-tuning knob;Since there is no safe relief device, it is suggested to install a relief valve on the outlet pipeline of the pump

- Data sheet

| Max Discharge Pressure | 95 MPa |

| Max Discharge Flow Rate per Pump Head | 12100 L/h |

| Flow rate can besteplessy adjusted range | 0-100% |

| Metering accouraoy reaches | ±0.5% |

| Capacity Range per Pump Head | ≤12800 L/h |

| Pressure Range | ≤1.2 MPa |

Complete Guide

Mechanical Diaphragm Metering Pump DPMFXWAD90-0.3-III

Working principle, The motor drives worm gear pair, changes rotary motion of the motor into reciprocating movement of the slide rod through the eccentric mechanism, the slide rod drives the mechanical diaphragm to perform periodical deformation, thus realizing fluid suction and discharge.

Capacity Range per Pump Head: ≤2800 L/h; Pressure Range: ≤1.2 MPa;

A pump head can be made of 304, 316, 316L, 904, Hastelloy C, PVC, PVDF, PP, PTFE, etc.

- An advanced design of single diaphragm and double diaphragms uniformly forced through grinding, making diaphragms more durable;

- Double PTFE diaphragms show excellent corrosion resistance and leakage prevention;

- The diaphragm status monitoring system can send out signals when one diaphragm ruptures, the pump can continue working till diaphragm replacement or it can be stopped directly without any pollution to fluids;

- An accurate design of eccentric mechanism, including cam and spring eccentric mechanism, and integrated sleeve adjustable eccentric transmission mechanism;

- Static seal of diaphragm at hydraulic end replaces dynamic seal of plunger, ensuring no leakage during fluid transportation;

- Diaphragm movement directly driven by the slide bar replaces cyclic reciprocation of diaphragm hydraulically driven, so the structure of a mechanical diaphragm pump is simpler and makes maintenance more convenient;

- Depamu mechanical diaphragm pumps, in a patented design, ensure a stable flow output;

- Whether a pump is shut down or running, stable flow outputs can be steplessly adjusted via the fine-tuning knob;

- Since there is no safe relief device, it is suggested to install a relief valve on the outlet pipeline of the pump

It is widely used in industries of environment protection, pharmaceutical, paper, sewage treatment, urban water supply, cement grinding aid, new energy, etc.