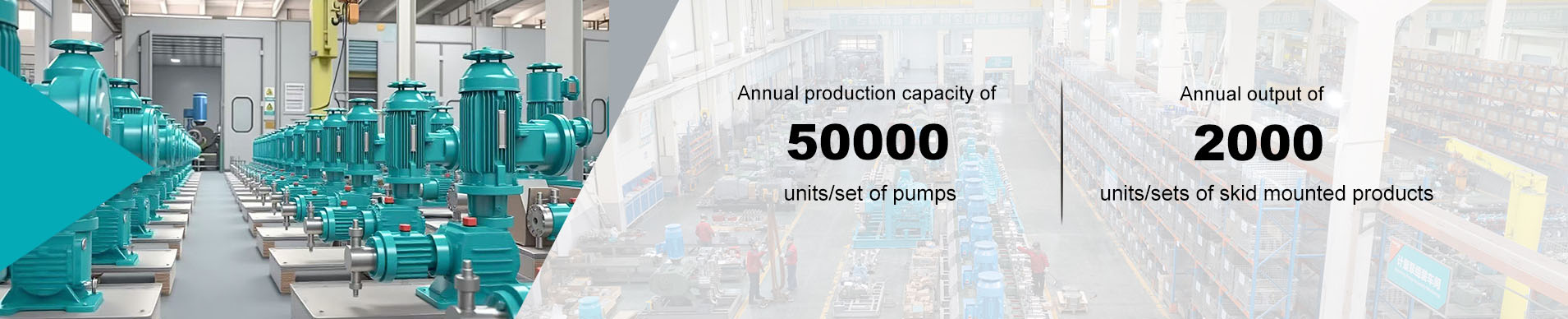

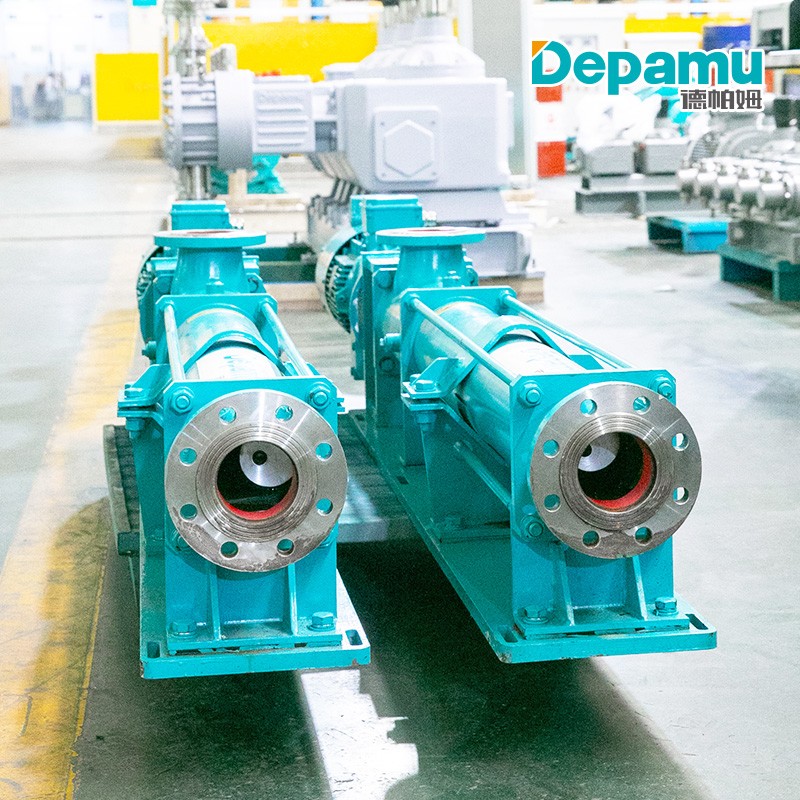

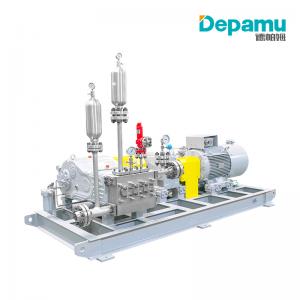

Single Screw Pump Single Screw Pump CLG070B03JBPDP

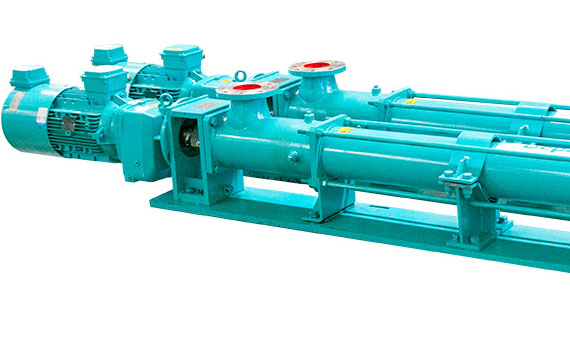

Based on advanced German technologies and professional technology certification, Depamu single screw pumps show obvious superiority in terms of special working conditions like fluids with a high viscosity, containing hard suspended particles, etc. featuring a long service life and reliable operation with many patents held of the first-rank international level.

Multiple modular structural combinations

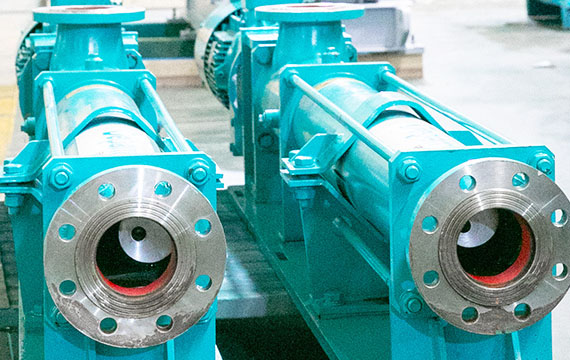

Able to rotate and transport fluids in both directions;No shearing or mixing during transfer ensures no damage to molecular chain structure and specific fluid properties formed during process.

The best suction capacity of 8m water column

Temperature range of pumped fluids: -12℃~+150℃

Products have won praise from users at home and abroad.

Flexible mounting types

Based on advanced German technologies and professional technology certification, Conilowa single screw pumps show obvious superiority in terms of special working conditions like fluids with a high viscosity, containing hard suspended particles, etc. featuring a long service life and reliable operation with many patents held of the first-rank international level.

- Data sheet

- Specification

| Multiple modular structural combinations | Support |

| Able to rotate and transport fluids in both directions | Support |

| Temperature range of pumped fluids | -12℃~+150℃ |

| The best suction capacity | 8m water column |

Complete Guide

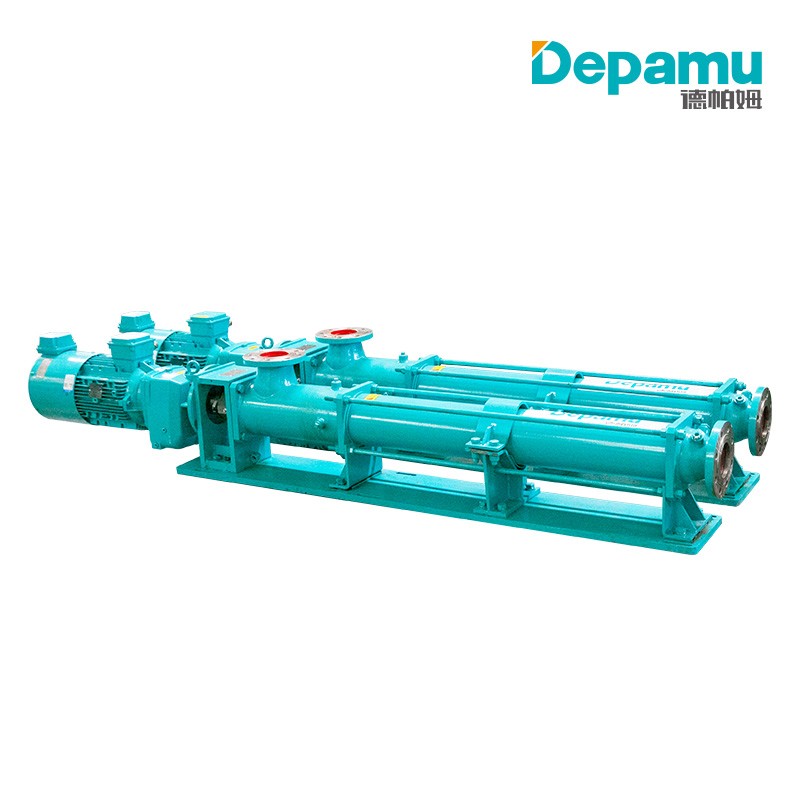

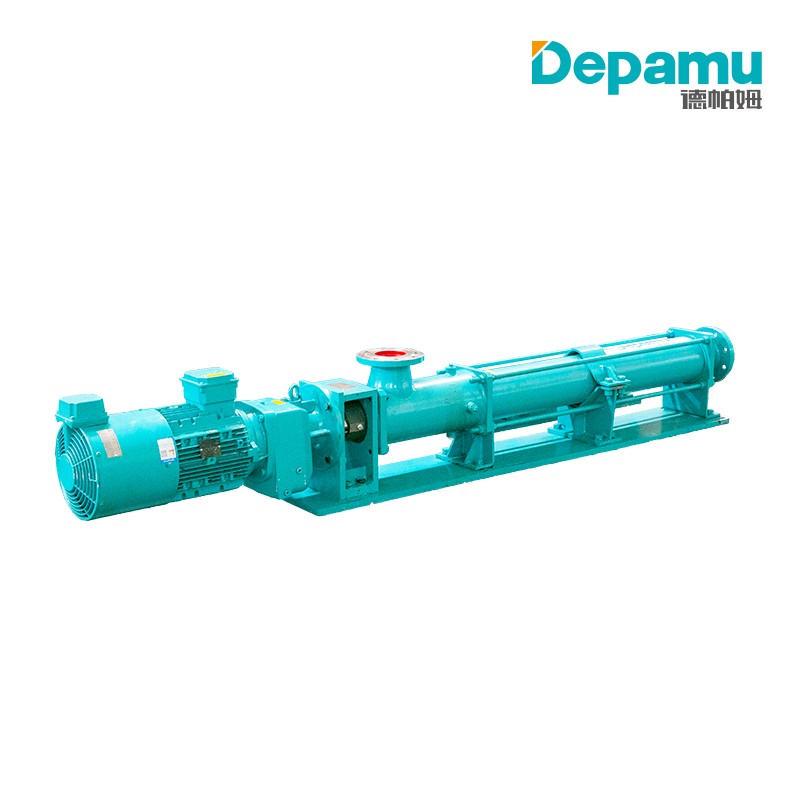

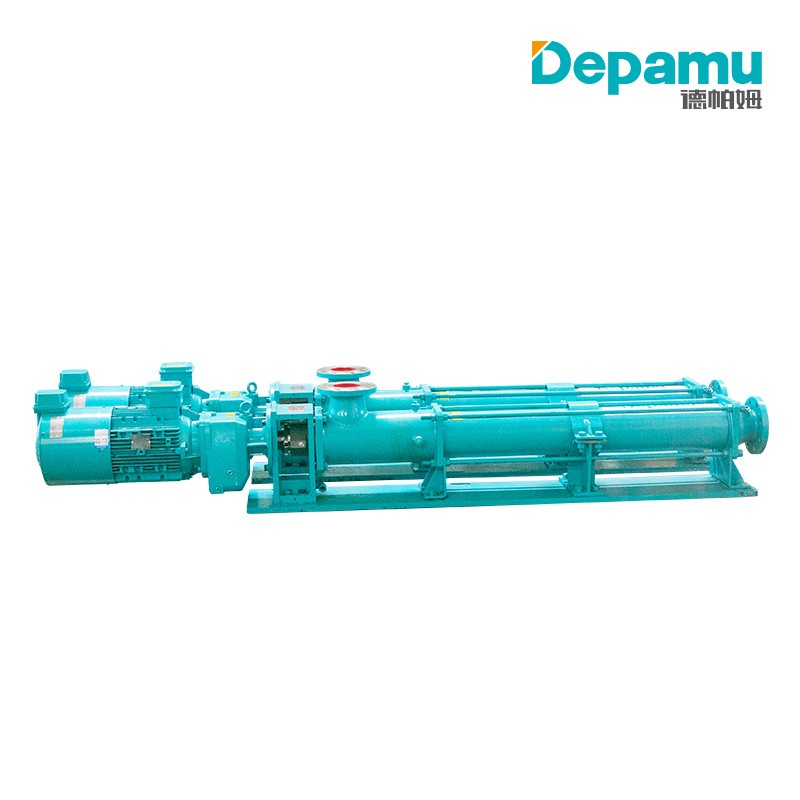

Single Screw Pump Single Screw Pump CLG070B03JBPDP

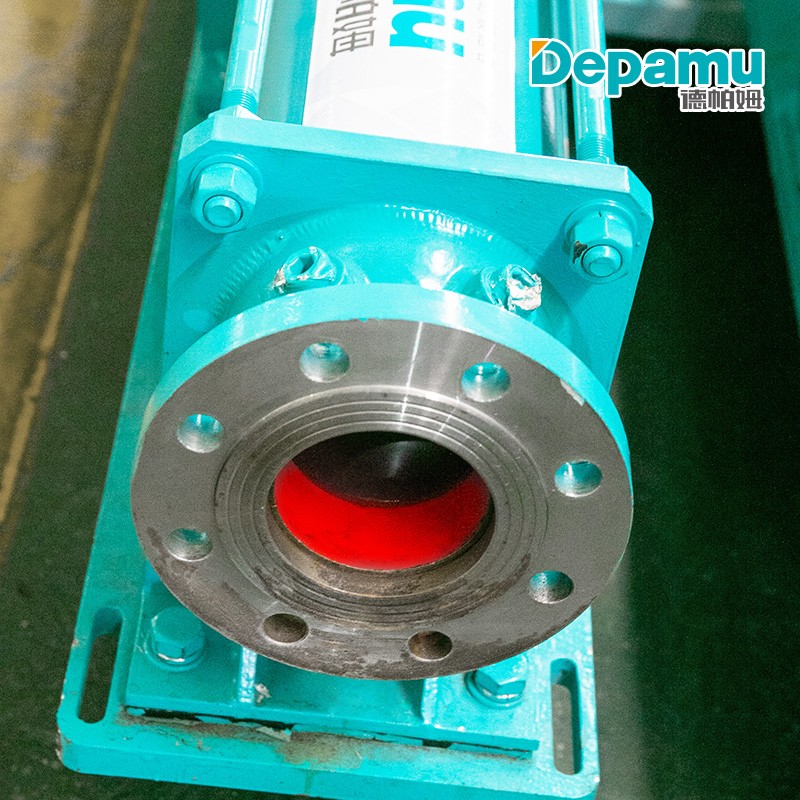

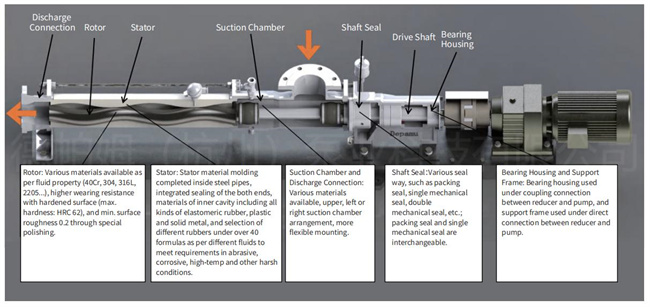

Working principle, As a rotary positive displacement pump, a single screw pump transfers liquids mainly based on volumetric change generated in suction chamber and discharge chamber from intermeshing of screw and lining. As an internally engaged and enclosed positive displacement pump, its main working components are rubber lining (stator) with spiral empty chamber, and spiral screw (rotor) engaging with lining in chamber. When input shaft drives rotor to make planetary rotations around stator center through universal joint, stator and rotor continuously mesh to form enclosed cavities, which make uniform axial motions in a constant volume and transfer fluids from suction end to discharge end via stator and rotor.

Screw pumps are suitable for transport of media below: media with a big content of solids (max. particle size 30mm); media of different viscosities (1mpas~1,000,000 mpas); media with thixotropy and expansibility; media with shear sensitivity; corrosive media (pH=0~14); media with/without self-lubricity; abrasive media; cohesive media; toxic media; mixed media containing gas, solid or fiber.

- Petroleum and Petrochemical Light and heavy oil, acid, alkali and salt solution, viscous chemical paste, emulsion and slurry, oil-water separation and waste oil recovery system, polymer transfer.

- Environmental ProtectionIndustrial and domestic sewage treatment, oily water treatment, transfer of sludge and muddy water with solid particle and short fiber, oil-water separation and waste gas engineering, metering and dosing of flocculant and chemical agent.

- Exploitation and MiningTransfer of drilling mud, mining water supply and drainage, mining duster water supply, preparation, loading and grouting of mortar, concrete, titanium dioxide and kaolin sprayed on mine laneway wall.

- Medicine and FoodTransfer of medical ointment, syrup, jam, fermentation broth, honey, cream, starch paste, toothpaste, etc.

- Shipping Industry Bilge cleaning pump, marine incinerator transfer pump, oil-water separator pump, transfer of engine room oily water, etc.

- Energy IndustryTransfer of fuel oil, coal water slurry, resin and additive

- Paper-making Industry Transfer of paper pulp and short fiber slurry, slurry and waste water treatment, chemical metering, raw material preparation, coating and coloring process

- Building IndustryPaste transfer like cement mortar, painting, lime milk, etc.

- Electrolyte TreatmentTransfer of paste, emulsion, suspension as well as fluid requiring no stirring or shearing.

- Mechanical Engineering Oil-water mixture, sludge with metal, metallurgy slurry and waste tank emptying.

Principles and Characteristics of Stators and Rotors under Different Working Conditions A Conilowa single screw pump is a rotary positive displacement pump with the rotary rotor in the stator as the transfer element. The four geometrical shapes of a single screw pump share the same outline dimensions, so a standard structure is adopted; except rotor and stator, all the rest parts are the same for the four shapes. In case of demand in change of flow or pressure, mere change in rotor and stator of a single screw pump can make it suitable for operation under new conditions.

-

G/L Shape Single-thread screw/rotor with circular cross-section, long screw pitch and long thread depth; the thread depth changes continuously when the rotor rotates in the stator. The cross-section area of the stator is the same with that of the rotor, and the stator has double internal threads separated by 180。; so, when the rotor and the stator mesh, a cavity is formed in-between with an area of 1/2 stator. When the rotor rotates, the progressive cavity between the rotor and the stator stably and continuously transfers fluid inside the cavity from suction end to discharge end. Flow depends on rotor/stator screw pitch, diameter and eccentricity as well as pump speed. Discharge pressure depends on number of stages and max. 6bar (85psi) differential pressure for each stage.

A G-shape 2-stage Conilowa pump can realize a differential pressure at 12bar (170psi) and a flow at 100%. A .-shape 1-stage pump shares the same appearance, diameter and eccentricity with a G-shape 2-stage pump, and its screw pitch is twice of rotor/stator screw pitch of a G-shape 2-stage pump; therefore, .-shape 1-stage pump can realize a flow twice of a G-shape 2-stage pump with max. 6bar (85psi) differential pressure.

- G Shape 1. Very stable transfer;2.Compact structure;3.Large cross-section area of rotor feed;4.Small flow velocity/NPSH;5. Able to transfer viscous materials;6. Able to transfer materials containing large-particle solids.

- L Shape A high volumetric efficiency and a long service life due to a long sealing line between rotor and stator; Compact structure and big flow.

-

D/P Shape Double-thread rotor with elliptical cross-section, long screw pitch and long thread depth; the rotor makes eccentric circular rotations in the stator. The stator has the same shape with that of the rotor, and the stator has three internal threads with every two separated by 120。; so, when the rotor and the stator mesh, a cavity is formed in-between with an area of 2/3. When the rotor rotates, the progressive cavity between the rotor and the stator stably and continuously transfers fluid from suction end to discharge end. Flow depends on rotor/stator screw pitch, oval diameter and eccentricity as well as pump speed. Pressure performance depends on number of stages and max. 6bar (85psi) differential pressure of each stage.

D/P-shape cavity has a size about 75% of G/.-shape, opens twice every rotation while G/.-shape cavity only opens once every rotation. So, D/P-shape rotor/stator has a flow 50% more than that of G/.-shape in every rotation. D-shape 2-stage pump can realize a max. differential pressure 12bar (170psi) under a flow 150% of G-shape 1-stage pump flow. P-shape Conilowa 1-stage pump shares the same appearance, elliptical diameter and eccentricity with D-shape 2-stage pump, and its screw pitch is twice of rotor/stator screw pitch of a D-shape 2-stage pump; therefore, it can realize a flow 300% of G-shape pump under the max. differential pressure 6bar (85psi).

- D ShapeCompact structure regardless of pressure or flow;Nearly no pulsation during transfer;A high metering accuracy.

- P Shape Compact structure regardless of flow and nearly no pulsation during transfer;A high metering accuracy;A high volumetric efficiency and a long service life due to a long sealing line between rotor and stator.